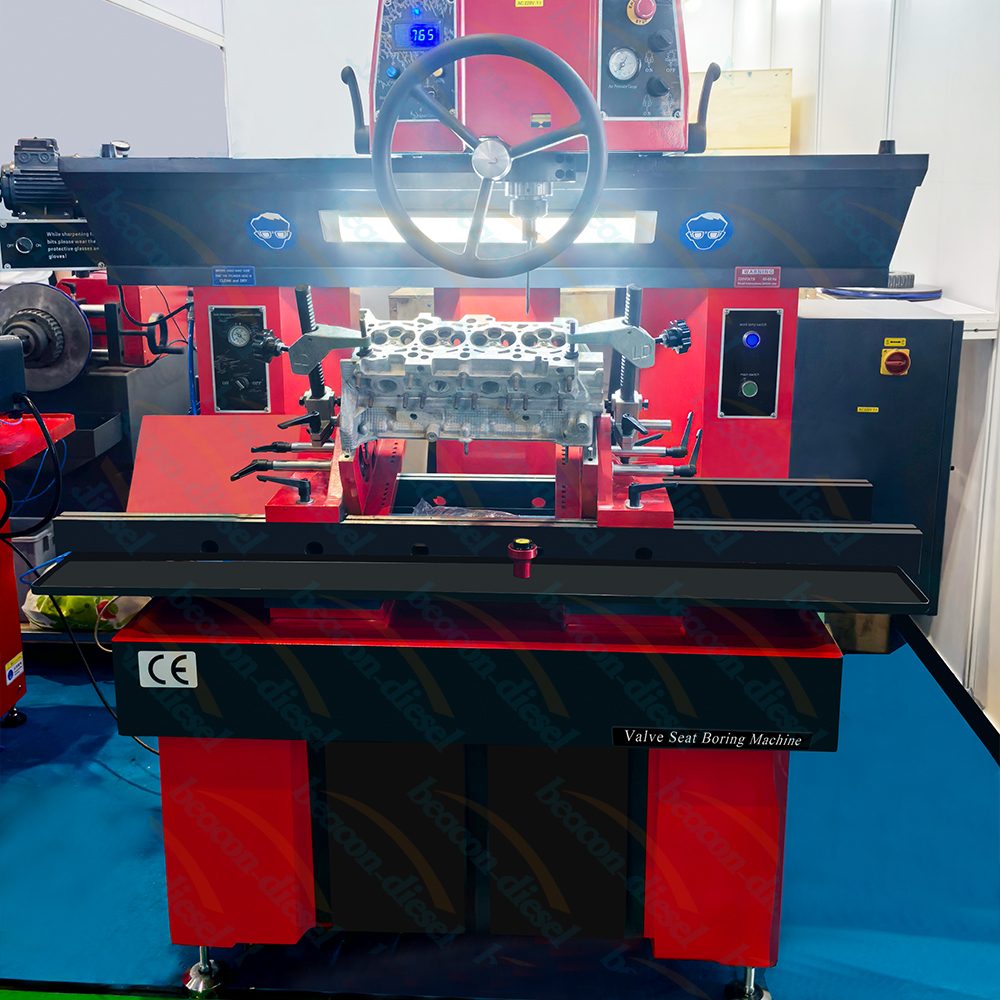

GS-180B Precision Valve Seat Boring Machine for High-Hardness Cylinder Heads

Details

The GS-180B Valve Seat Boring Machine is a new generation of high-precision equipment specifically designed for boring specialized hard valve seats and guiding tubes. It is particularly effective for the demanding requirements of new energy gas engines.

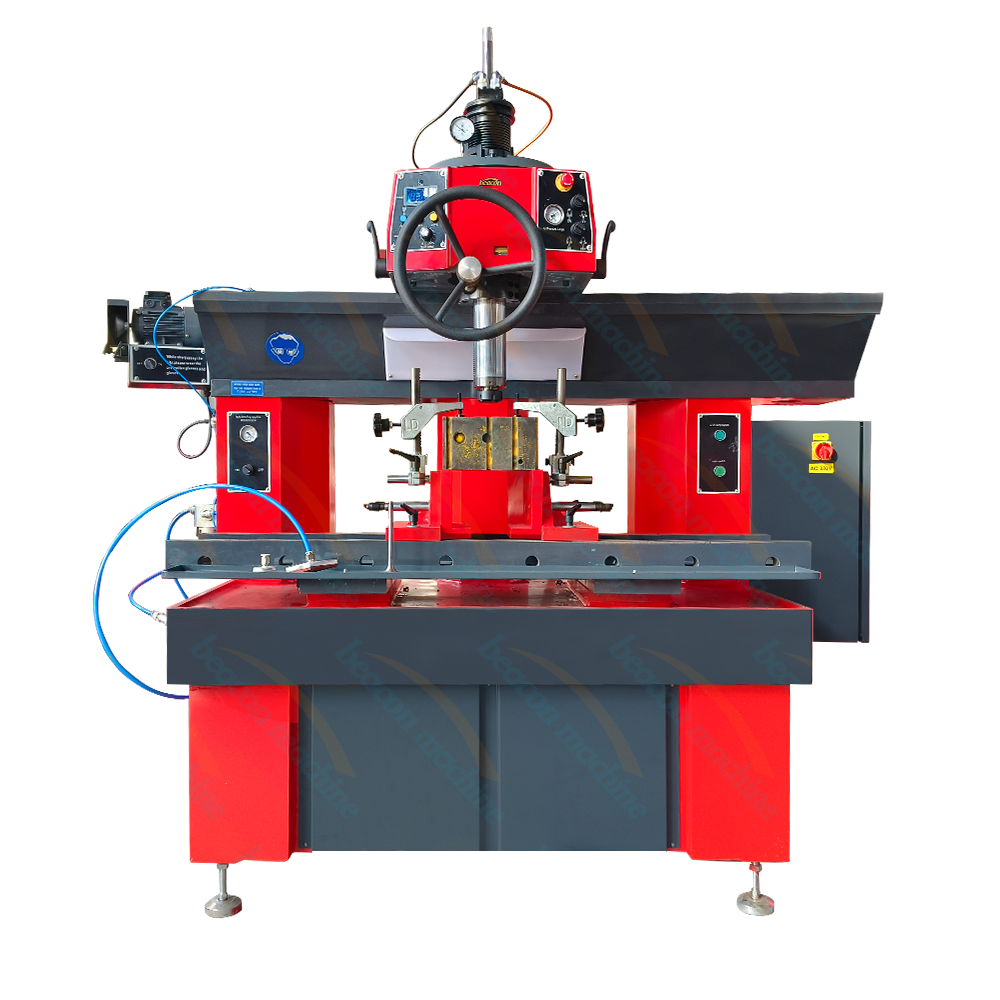

Equipped with a newly designed air float table, it offers superior flexibility when handling heavy cylinder heads. The machine utilizes a state-of-the-art T-slot device for rapid fixing, ensuring more stable performance and significantly lower noise levels compared to traditional vacuum-locking devices. With its extended machining capacity (up to 90mm), it is an essential tool for high-end engine remanufacturing.

GS-180B Precision Valve Seat Boring Machine for High-Hardness Cylinder Heads Advantage

Extended Machining Range: Larger capacity compared to standard models, supporting diameters from 14mm up to 90mm.

Advanced Air Float Table: Provides effortless flexibility and movement for heavy and large cylinder heads.

Efficient T-Slot Fixing: Replaces old vacuum systems for faster setup, increased stability, and reduced compressed air consumption.

Enhanced Cutting Power: Features new blade technology that provides 30% more cutting power, easily handling the hardest alloy seats.

Optimized for Gas Engines: Designed specifically for the high-precision needs of new energy and high-performance gas engine components.

Stability & Noise Reduction: Precision engineering ensures a vibration-free operation and a quieter workshop environment.

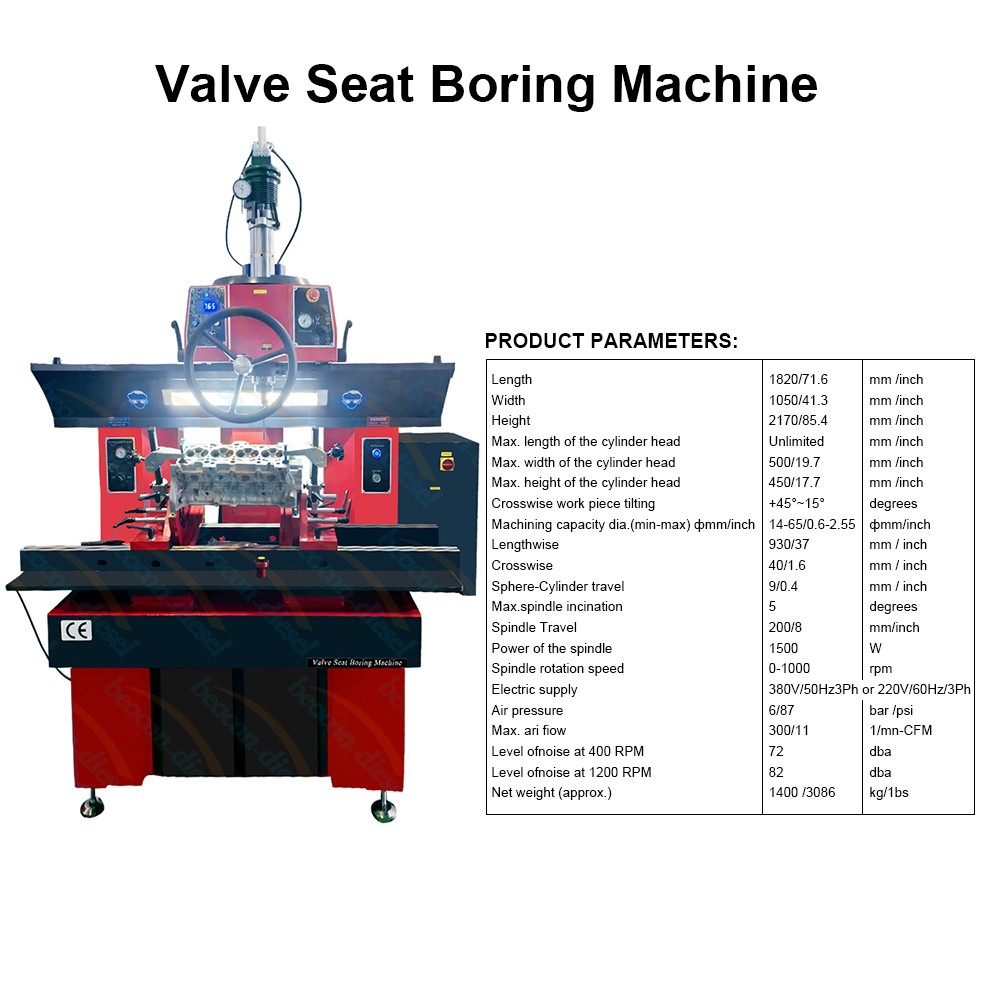

parameter

| Items | Parameter | Unit |

|---|---|---|

| Machining Capacity (dia.) | 14 - 90 / 0.6 - 2.95 | mm / inch |

| Max. Cylinder Head Height | 450 / 17.7 | mm / inch |

| Max. Cylinder Head Width | 500 / 19.7 | mm / inch |

| Spindle Travel | 200 / 8.5 | mm / inch |

| Spindle Speed | 0 - 1000 | RPM |

| Work Piece Tilting | +45° ~ -15° | Degrees |

| Spindle Inclination | 5.5 | Degrees |

| Overall Dimensions (LxWxH) | 1050 x 1150 x 1150 | mm |

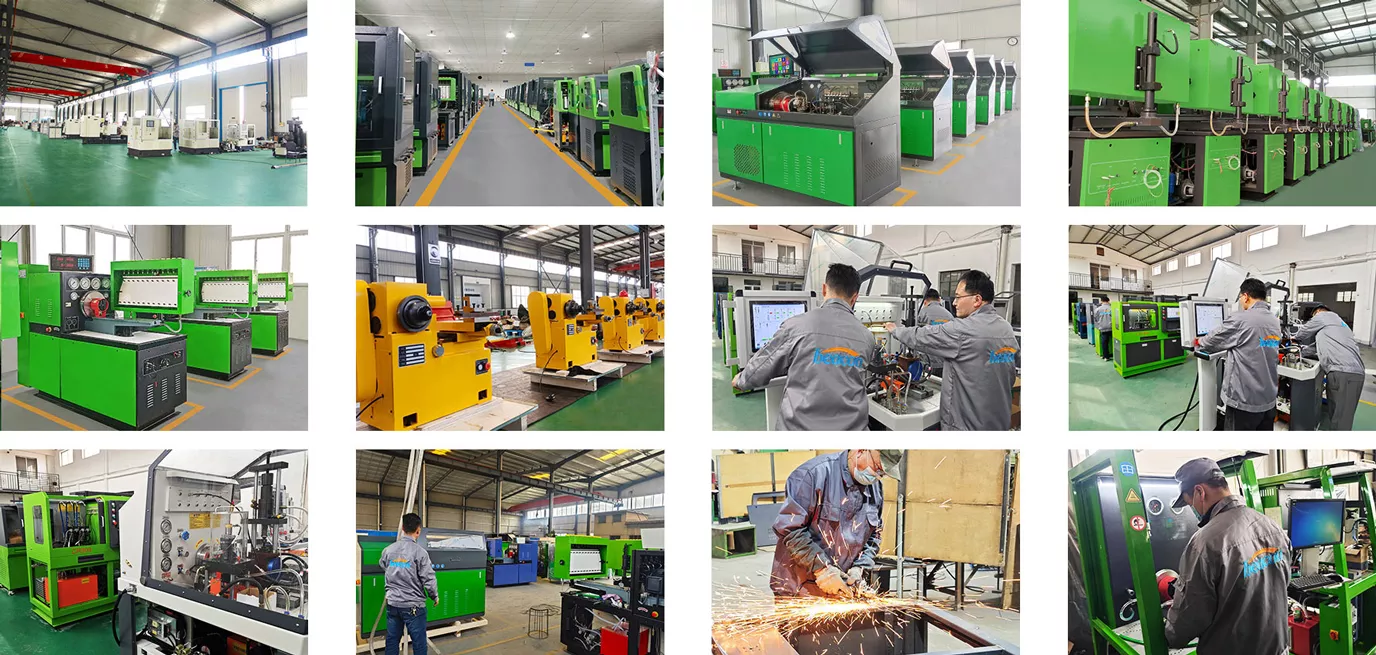

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language