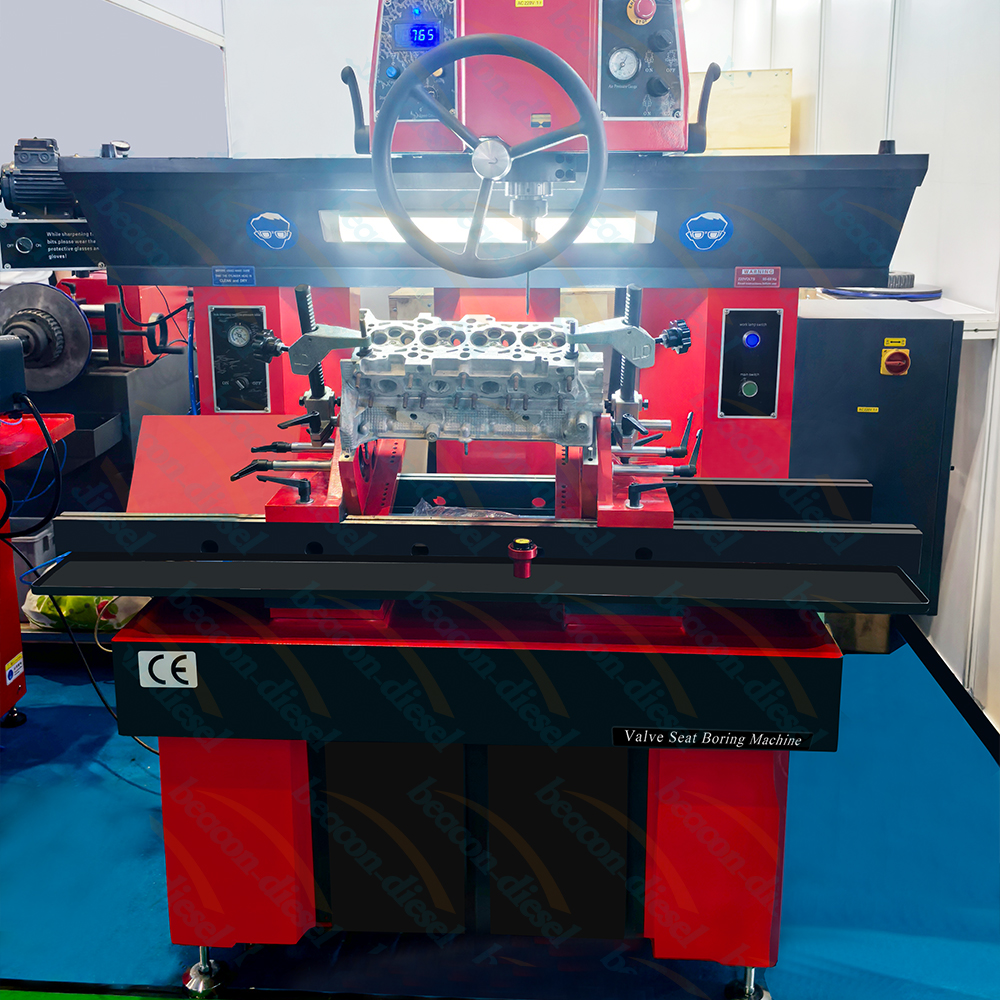

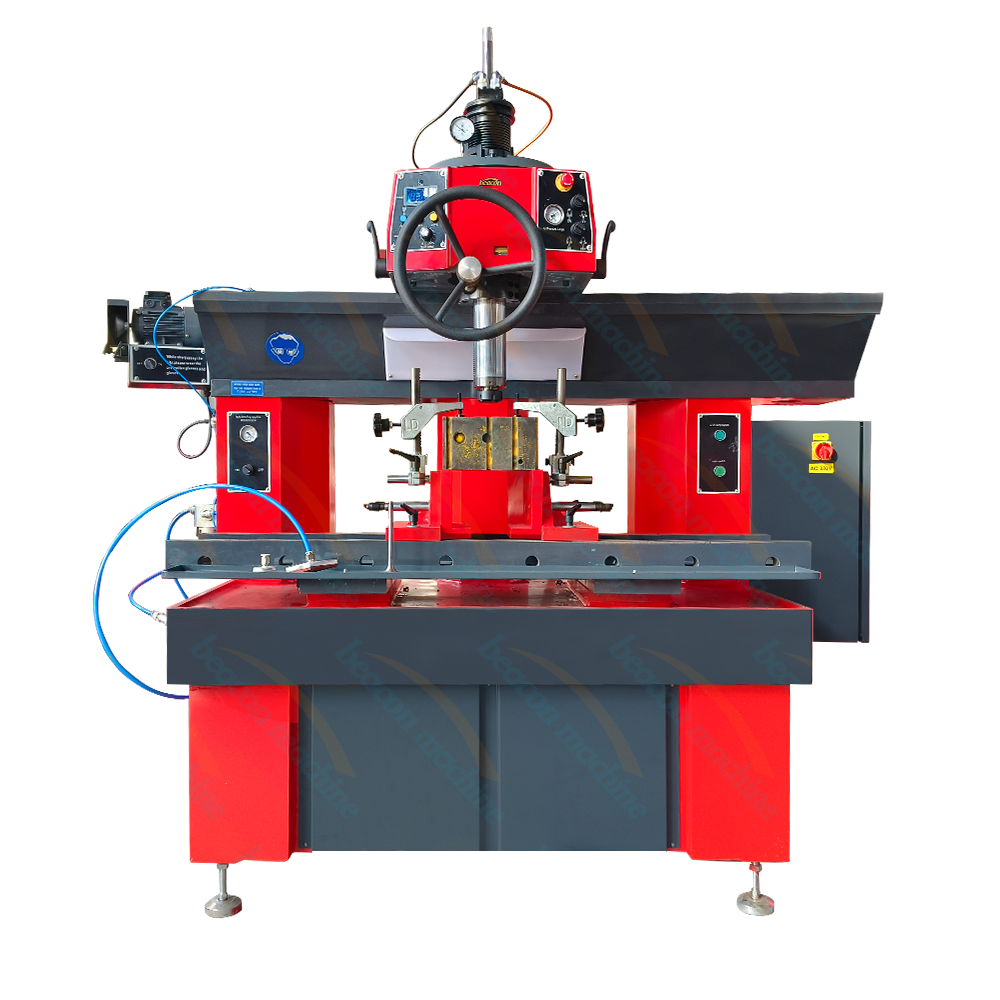

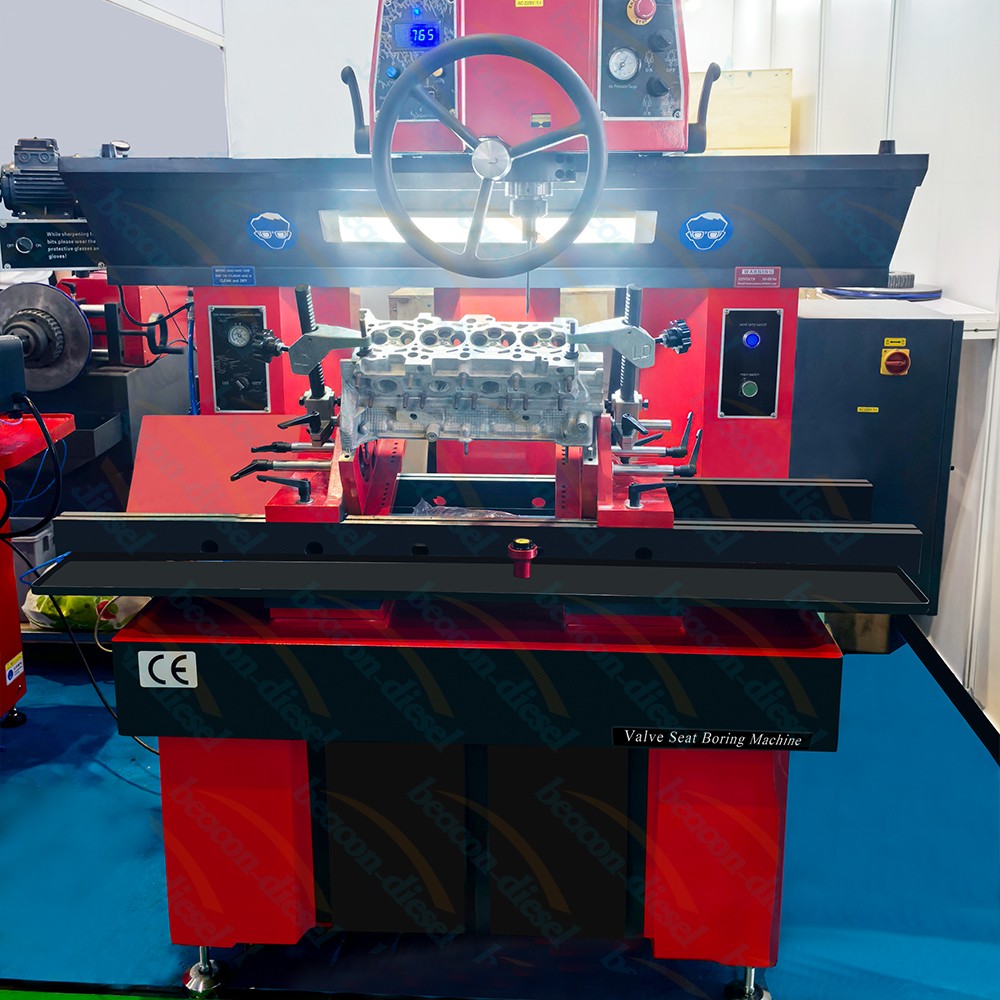

GS-180A High-Precision Valve Seat Boring Machine for Heavy-Duty Cylinder Heads

Details

The GS-180A Valve Seat Boring Machine represents a new generation of engine repair technology. Specifically engineered for the high-precision boring of specialized hard valve seats and guiding tubes, it is particularly effective for new energy gas engines.

Equipped with a state-of-the-art air float table, the GS-180A provides exceptional flexibility even when handling the heaviest cylinder heads. The integration of a T-slot device allows for rapid fixing of the air float head, significantly improving workflow efficiency. This machine is designed to deliver an unparalleled machining experience with reduced noise and enhanced stability compared to traditional vacuum-locking models.

GS-180A High-Precision Valve Seat Boring Machine for Heavy-Duty Cylinder Heads Advantage

New Air Float Table: Enhanced flexibility for maneuvering and positioning heavy cylinder heads with ease.

Advanced T-Slot Device: Replaces old vacuum locking systems, providing faster fixing and more stable performance while saving pre-pressurized air.

Superior Cutting Power: Newly designed blades provide 30% more cutting power, ideal for the hardest alloy valve seats.

Low Noise Operation: Optimized mechanical structure reduces operational noise for a better workshop environment.

High Precision: Engineered for the strict tolerances required by new energy gas engines and high-performance components.

Universal Capability: Accommodates cylinder heads of unlimited length and features a wide crosswise work piece tilting range (+45° to -15°).

parameter

| Items | Parameter | Unit |

|---|---|---|

| Machining Capacity (dia.) | 14 - 70 / 0.6 - 2.29 | mm / inch |

| Max. Cylinder Head Height | 450 / 17.7 | mm / inch |

| Max. Cylinder Head Width | 500 / 19.7 | mm / inch |

| Spindle Travel | 200 / 8.5 | mm / inch |

| Spindle Speed | 0 - 1000 | RPM |

| Work Piece Tilting | +45° ~ -15° | Degrees |

| Spindle Inclination | 5.5 | Degrees |

| Dimensions (LxWxH) | 2000 x 2100 x 2250 | mm |

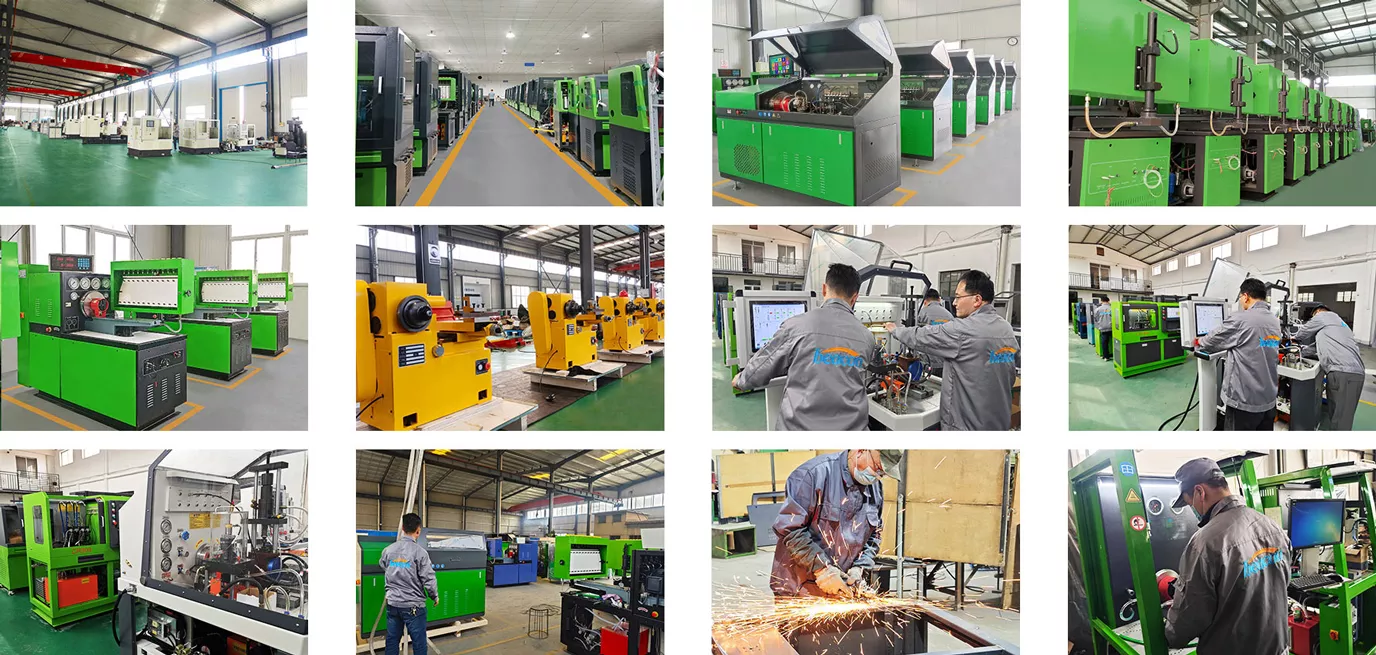

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language