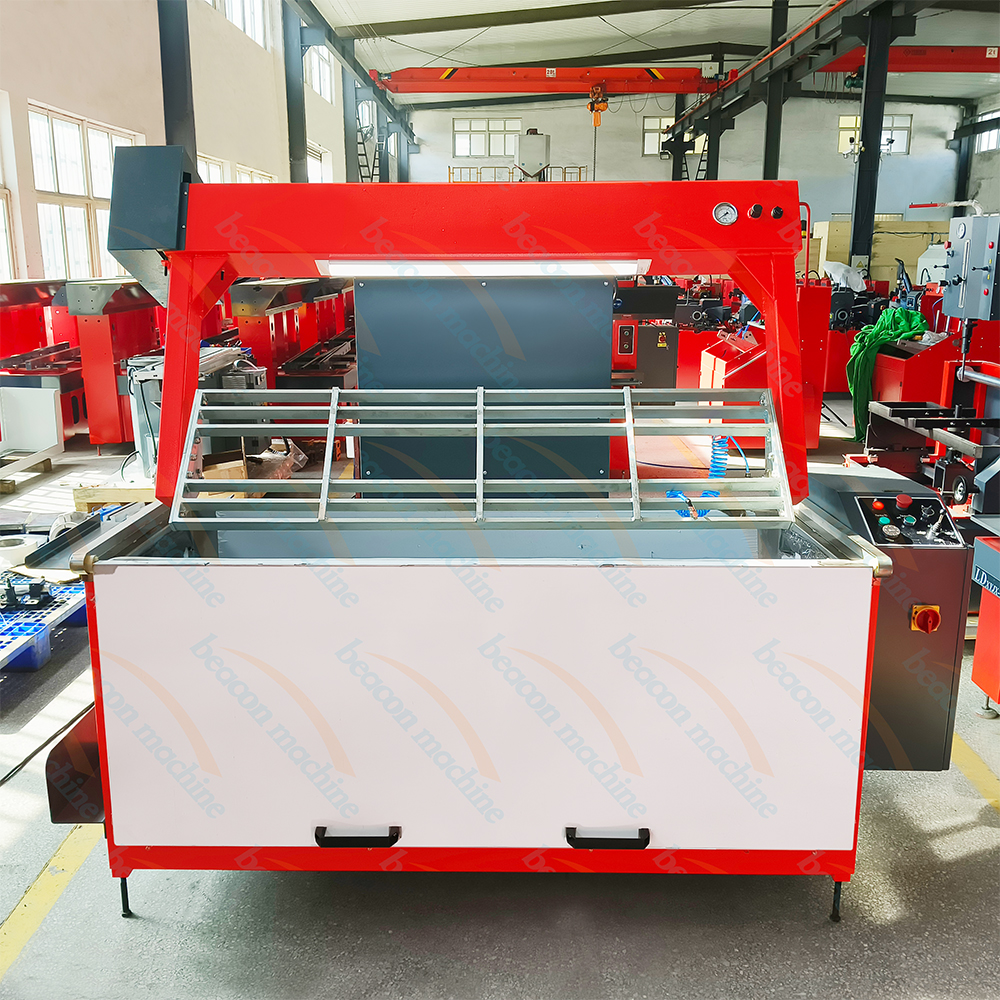

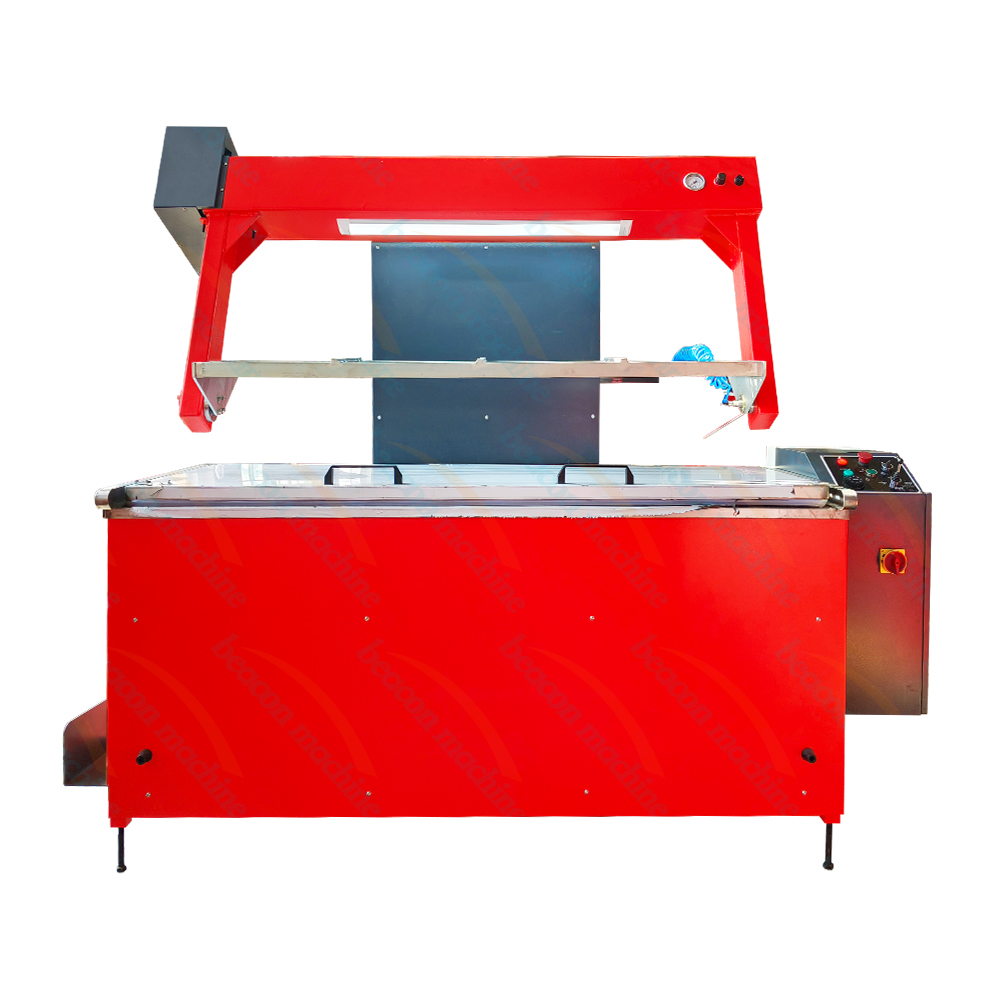

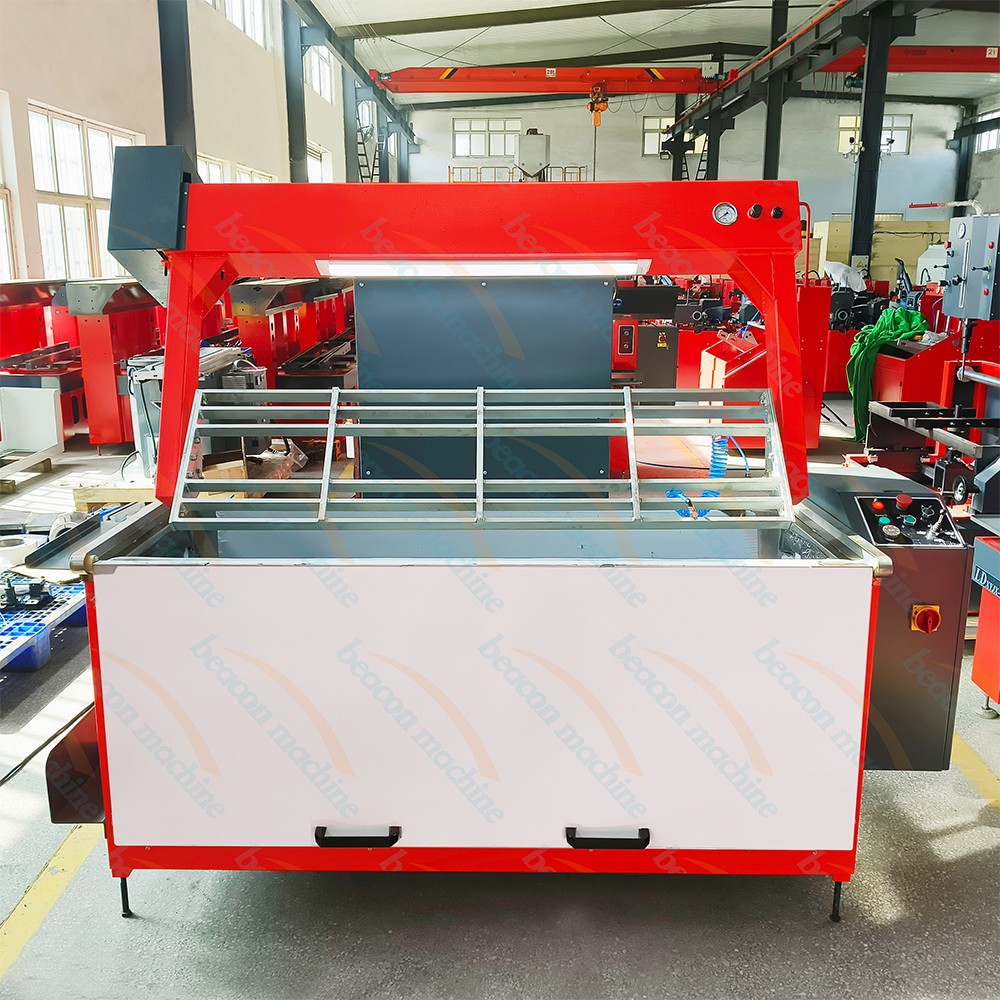

GS-1750 Industrial Cylinder Head and Engine Block Pressure Tester Leak Detection Machine

Details

The GS-1750 Cylinder Head and Block Pressure Tester is a high-efficiency diagnostic station specifically designed for testing the sealing and structural integrity of large engine components. By combining pneumatic, electrical, and hydraulic systems, it provides a comprehensive solution for detecting cracks and defects in cylinder heads and engine blocks.

The GS-1750 stands out for its ability to simulate the engine's real driving temperature by heating the water tank up to 90°C, making hidden cracks visible under thermal expansion. With its motorized 360° rotation bracket, operators can easily manipulate heavy components for a thorough inspection from any angle, ensuring the highest standards of engine repair and remanufacturing.

GS-1750 Industrial Cylinder Head and Engine Block Pressure Tester Leak Detection Machine Advantage

Large Testing Capacity: Specifically designed for larger engine heads and blocks compared to standard models.

Thermal Simulation: Built-in 11KW heating system simulates real engine operating temperatures to identify temperature-sensitive leaks.

360° Motorized Rotation: Equipped with an infinite flip bracket for easy inspection of all surfaces without manual lifting.

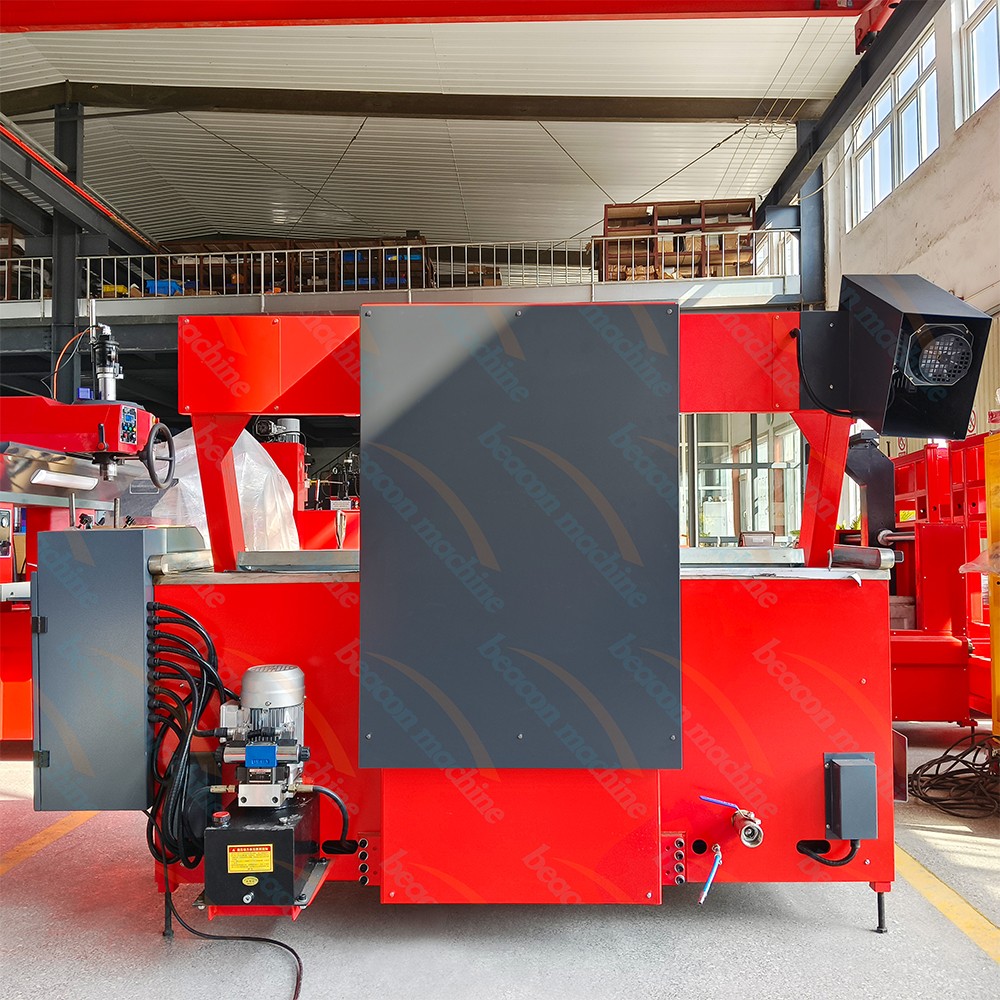

Integrated Multi-System: Seamlessly integrates hydraulic lifting, pneumatic pressure, and electrical controls.

Precise Leak Detection: High-sensitivity pressure monitoring ensures even the smallest microscopic cracks are identified.

Durable Design: Industrial-grade build quality suitable for continuous use in busy engine repair shops and factories.

parameter

| Technical Items | Specifications (GS-1750) |

|---|---|

| Max. Head Capacities (LxWxH) | 1450 x 415 x 465 mm |

| Gear-Motor Power (Rotation) | 0.37 KW |

| Pump-Motor Power (Hydraulic) | 0.75 KW |

| Heating Elements Power | 11 KW (5.5 KW x 2) |

| Thermostat Adjustment Range | 0 - 92 °C |

| Bracket Rotational Speed | 4.5 Tr/min |

| Power Supply | 3x380V AC (50/60Hz) |

| Application | Large Cylinder Heads & Engine Blocks |

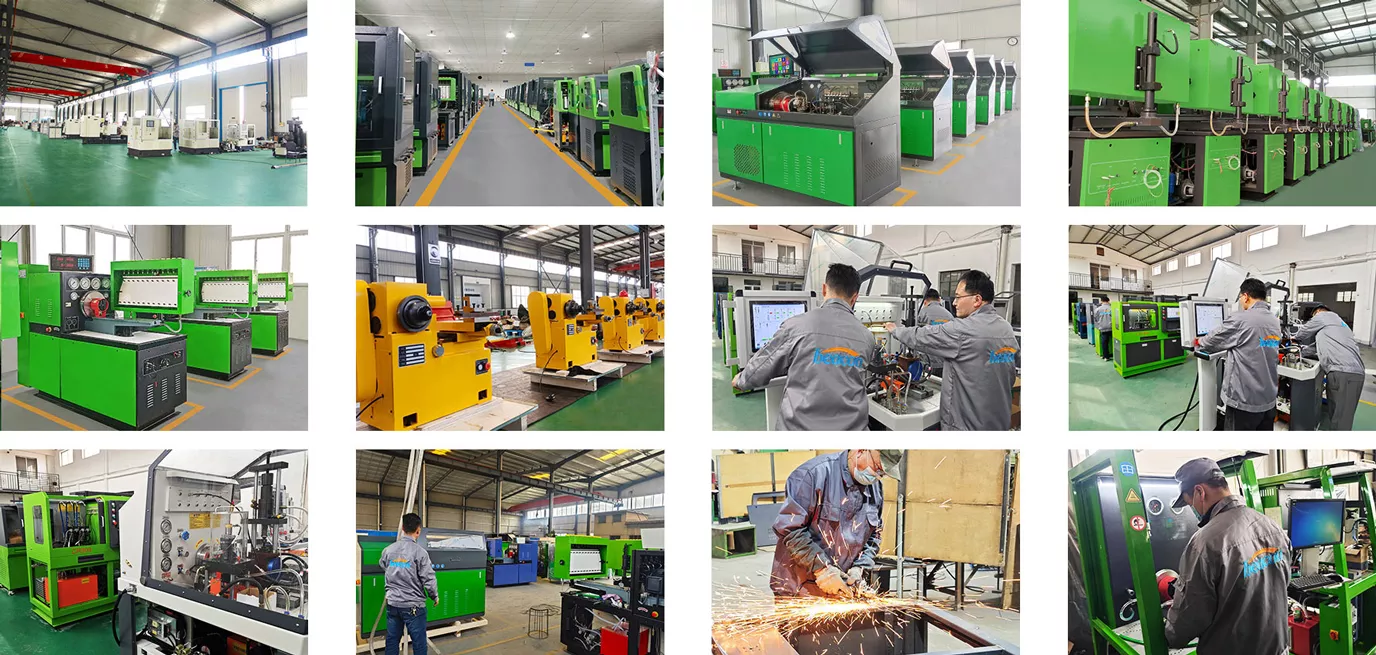

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language