CRS900S High-Performance Diesel Injection Pump Test Bench with Common Rail System

Details

The CRS900S Diesel Injection Pump Test Bench is a versatile and high-precision diagnostic solution designed for professional diesel workshops. This series adopts high-quality frequency conversion technology, characterized by ultra-low noise, energy efficiency, and high output torque.

Equipped with the advanced Beijing Common Rail System, the CRS900S can handle both traditional 12-cylinder Euro-standard mechanical fuel injection pumps and modern high-pressure common rail components. Its integrated flow sensor technology allows for real-time computer display and precise data analysis, making it a reliable tool for high-standard pump and injector calibration.

CRS900S High-Performance Diesel Injection Pump Test Bench with Common Rail System Advantage

Dual Testing Capability: Supports both traditional 12-cylinder mechanical pumps and advanced common rail systems.

High Reliability & Precision: Features high-quality frequency conversion and flow sensor technology for accurate, stable measurements.

Powerful Performance: Delivers high output torque while maintaining energy efficiency and ultra-low operational noise.

Advanced Control System: Integrated with the Beijing Common Rail System for intuitive operation and comprehensive data feedback.

Enhanced Safety: Built-in perfect auto-protecting functions prevent equipment damage during high-pressure testing.

Durability: A heavy-duty build (800KG) ensures long-term stability and professional performance in demanding environments.

parameter

| Technical Items | Specifications (CRS900S) |

|---|---|

| Power Output | 11KW / 15KW / 18.5KW / 22KW |

| Voltage Supply | 220V Single/3-Phase, 380V 3-Phase |

| Pump Compatibility | 12-Cylinder Euro Mechanical & Common Rail |

| Common Rail System | Beijing Common Rail System |

| Packaging Dimensions | 205 * 118 * 210 CM |

| Machine Weight | 800 KG |

| Measurement Method | Flow Sensor with Computer Display |

| Inverter Brand | LS (LG) Inverter |

video

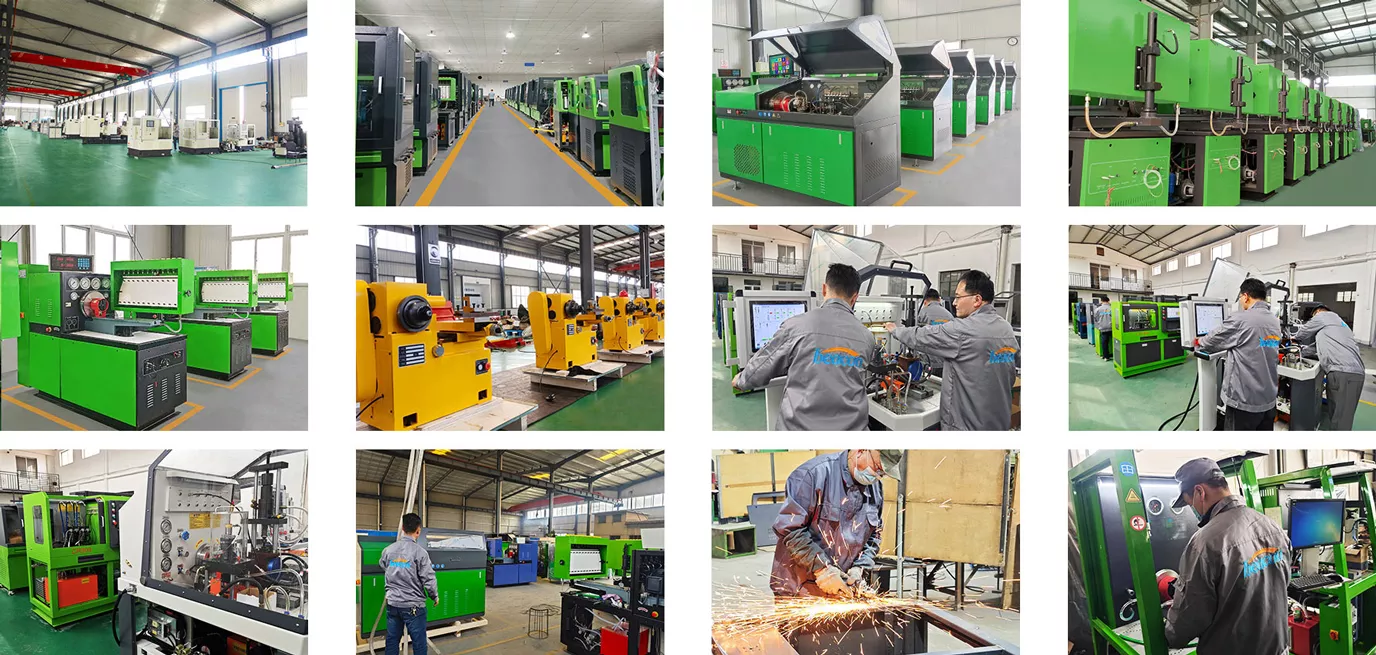

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language