YYQ-16 Series General Horizontal Hard Support Dynamic Balancing Machine Industrial Rotor Balancer

Details

The YYQ-16 Series is a professional-grade horizontal hard support dynamic balancing machine designed for high-efficiency and high-precision measurement. It features a robust roller bearing and gimbal coupling drive system, integrated with an industrial control computer. Running on a Windows-based measurement system, it provides real-time monitoring of imbalance values, phase angles, and speed. It is widely used for balancing rotors in motors, blowers, diesel engines, and textile machinery, supporting single-side, double-side, and multi-plane correction.

YYQ-16 Series General Horizontal Hard Support Dynamic Balancing Machine Industrial Rotor Balancer Advantage

High Precision & Efficiency: Advanced GB-2000 microcomputer system with high-speed A/D converters ensures accurate and rapid balancing data.

Hard Support Design: Provides a stable, integrally cast lathe bed for reliable measurement of axle-plate and overhanging rotors.

Intuitive Operation: Real-time LCD monitor displays all critical balancing parameters (imbalance amount, angle, and speed) simultaneously.

Variable Speed Control: "A" type models feature frequency conversion for stepless speed regulation, catering to diverse rotor types.

Versatile Application: Ideal for a wide range of industries including agricultural machinery, blowers, motors, and automotive crankshafts.

Stable Performance: Built to handle both lightweight and heavy-duty rotors with professional-grade durability and low maintenance.

parameter

| Item | Specification |

|---|---|

| Series Model | YYQ-16 General Horizontal |

| Support Method | Hard Support with Integrally Cast Bed |

| Measurement System | GB-2000 Microcomputer (Windows XP or above) |

| Drive Mode | Gimbal Couplings / Roller Bearing Drive |

| Speed Adjustment | Variable Frequency Speed Regulation |

| Real-time Display | Imbalance Value, Phase Angle, Speed (LCD) |

| Correction Planes | Single-side, Double-side, Multi-plane |

| Applicable Rotors | Motors, Blowers, Diesel Engine Crankshafts, Textile Machinery |

video

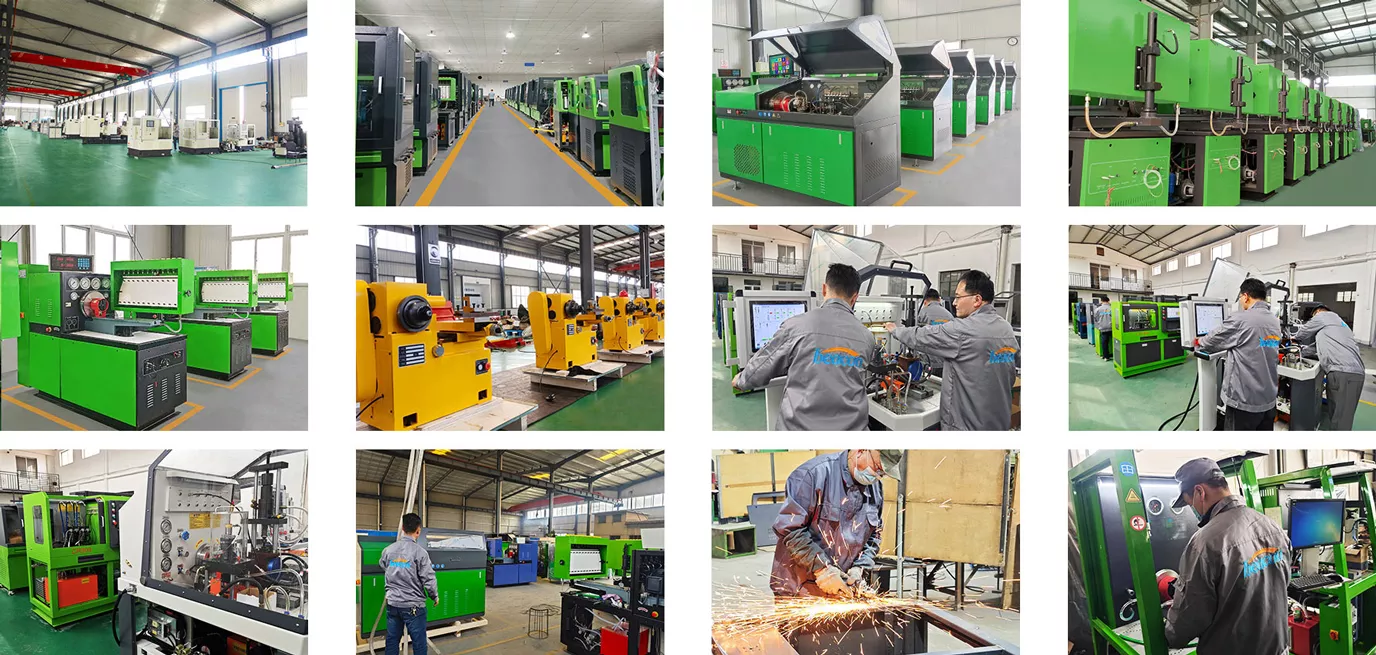

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language