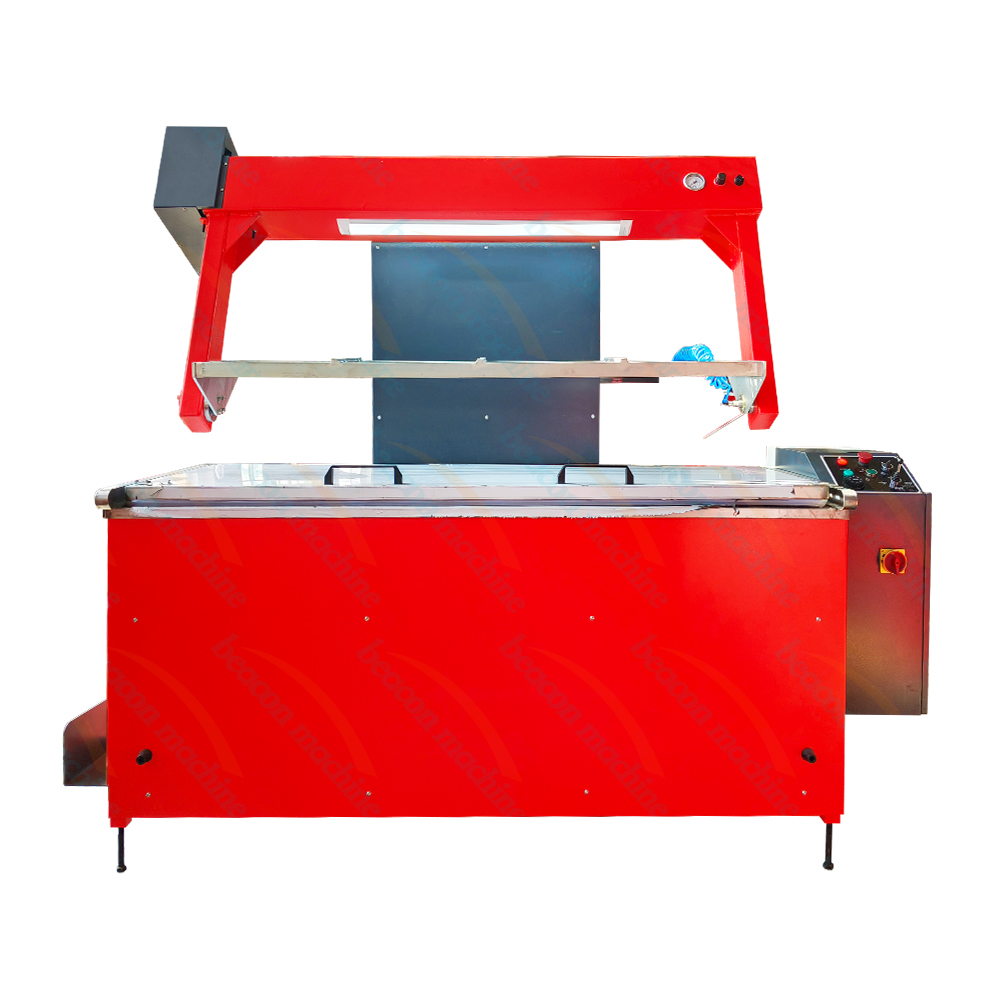

GS-1650 Cylinder Head and Block Pressure Tester for Engine Leak Detection

Details

The GS-1650 Cylinder Head and Block Pressure Tester is an advanced diagnostic equipment designed to detect cracks and leaks in engine components. By integrating pneumatic, electrical, and hydraulic technologies, it can simulate the actual working temperature of an engine to find even the smallest defects that only appear under heat.

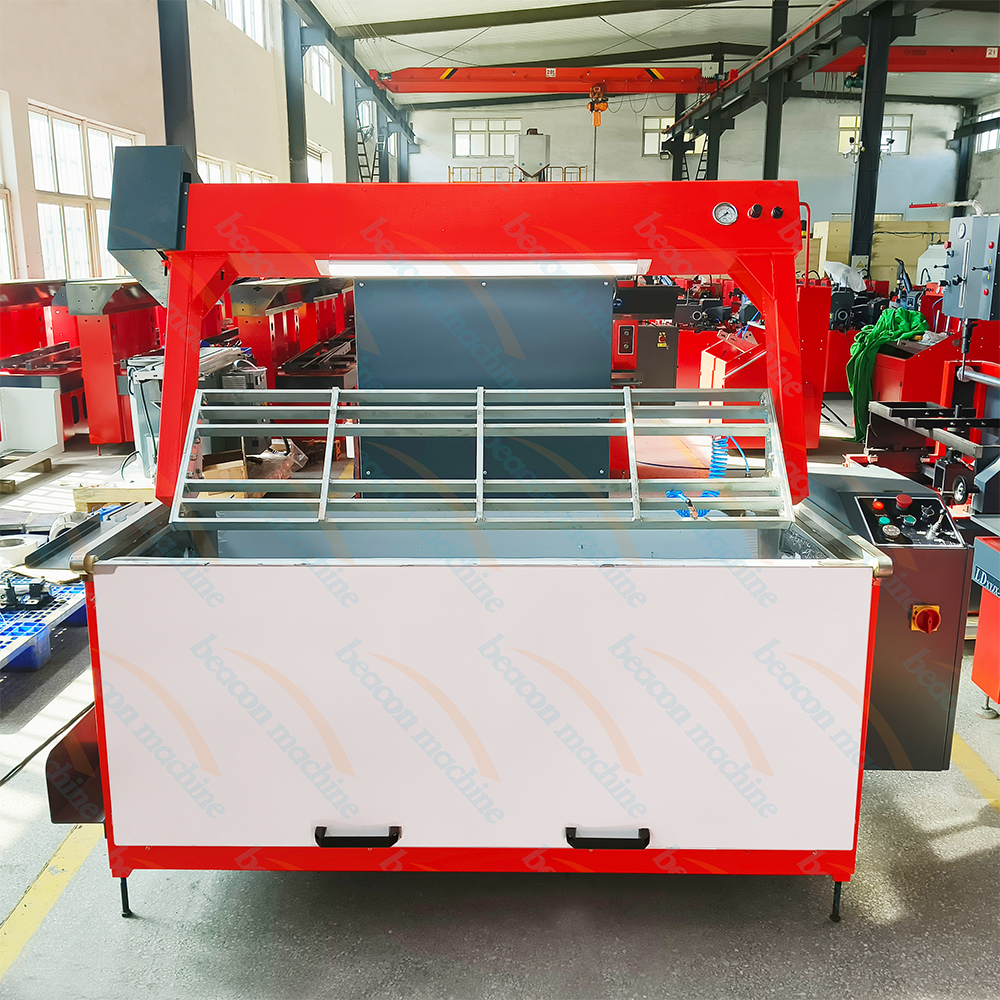

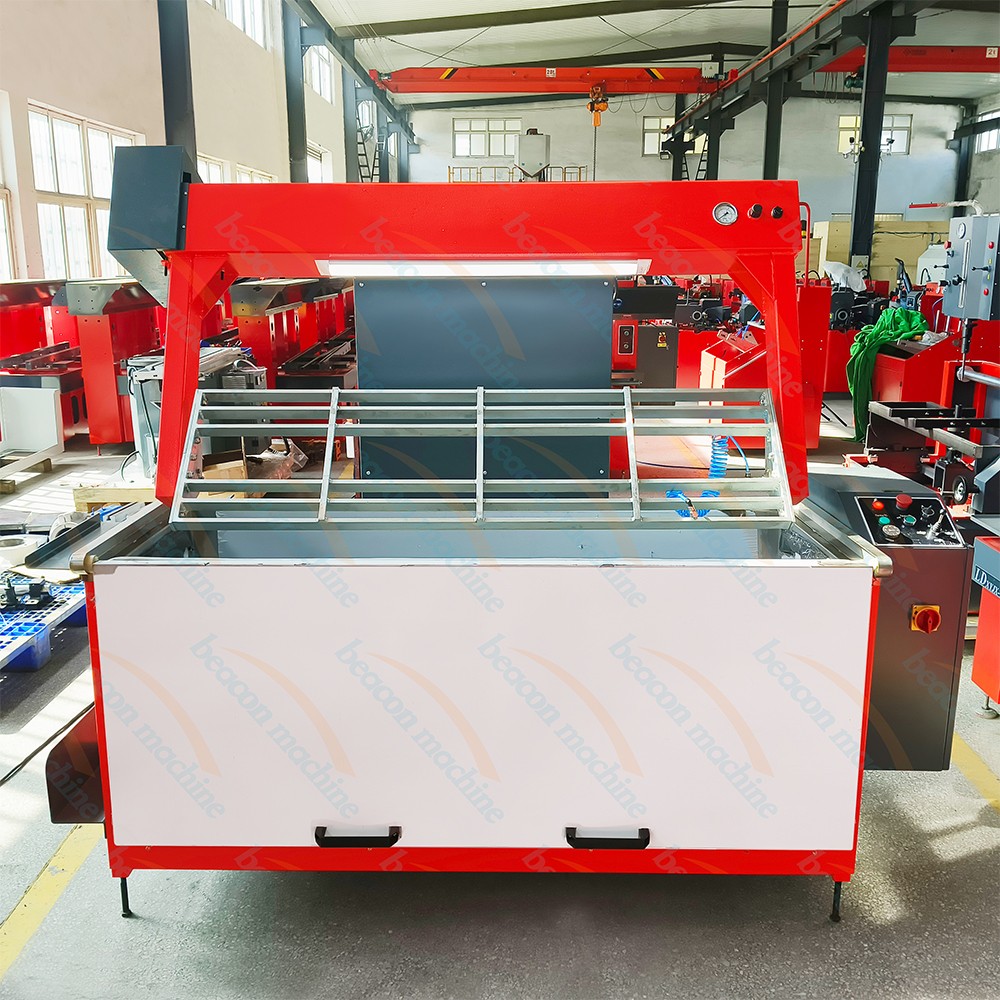

The machine is equipped with an infinite flip bracket, allowing operators to rotate the cylinder head or block easily to inspect every angle. It is an essential high-efficiency tool for engine remanufacturing centers and professional automotive workshops, ensuring that every repaired component meets safety and performance standards.

GS-1650 Cylinder Head and Block Pressure Tester for Engine Leak Detection Advantage

Simulated Operating Conditions: Capable of heating water to simulate engine temperatures, ensuring defects are found under realistic driving states.

360° Infinite Flip Bracket: Allows for easy rotation of heavy engine blocks and heads to locate cracks and defects accurately.

All-in-One Integration: Combines pneumatic, electrical, and hydraulic systems for a seamless and powerful testing process.

High Efficiency: Designed for rapid setup and testing, significantly reducing diagnostic time for engine repairs.

Durable Construction: Built with industrial-grade materials to withstand the heavy loads of large cylinder heads and blocks.

Precise Control: Features adjustable thermostats and motor speeds for customized testing procedures.

parameter

| Technical Items | Specifications (GS-1650) |

|---|---|

| Max. Head Capacities (LxWxH) | 1300 x 300 x 430 mm |

| Gear-Motor Power | 0.37 KW |

| Pump-Motor Power | 0.75 KW |

| Heating Elements | 2 x 5.5 KW |

| Thermostat Adjustment | 0 - 92 °C |

| Rotational Speed | 4.5 Tr/min |

| Power Supply | 3x380V AC (50/60HZ) |

| Tank Capacity | High capacity for large components |

video

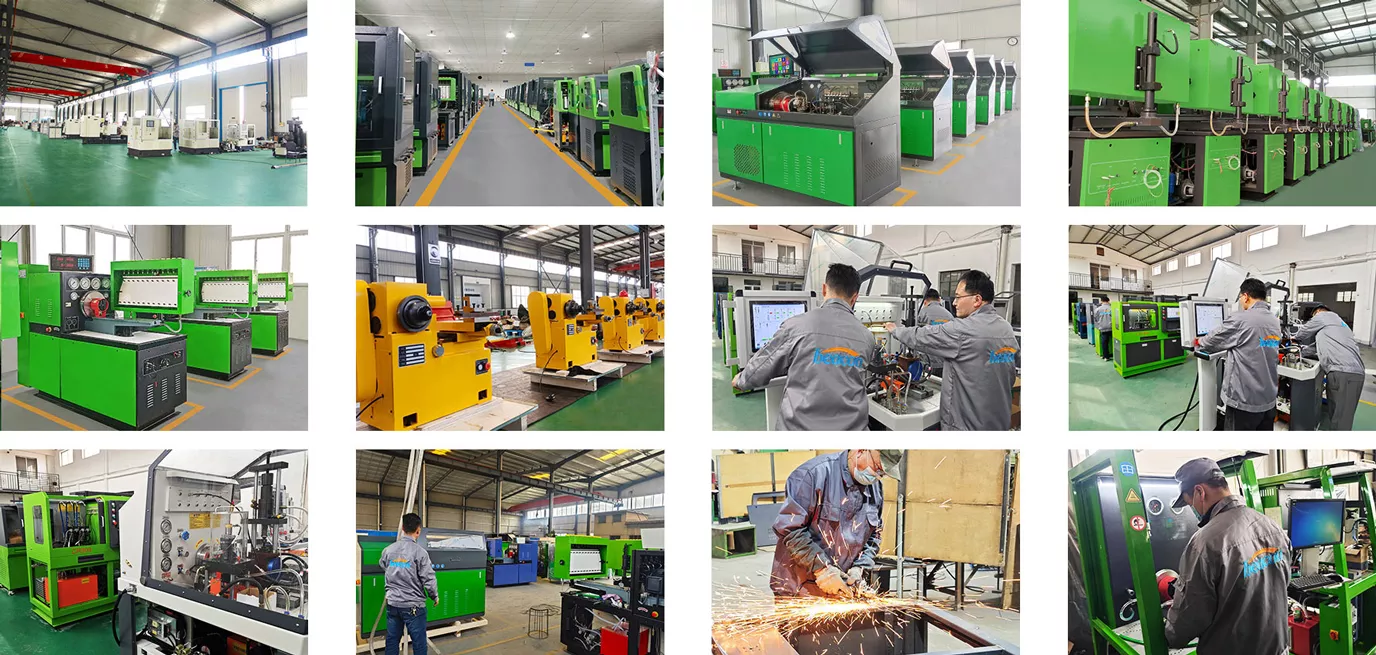

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language