EPS211 Common Rail Diesel Fuel Injector Testing Machine

Details

The EPS211 High Pressure Common Rail Injector Test Bench is designed to imitate diesel engine ECU control signals for a wide range of common rail systems, including Bosch, Denso, Delphi, and Siemens. This professional-grade equipment drives high-pressure common rail oil pumps and injectors, allowing maintenance personnel to accurately judge and repair the working state of the system. Controlled by an intuitive industrial computer interface, it provides comprehensive testing for sealing, full load, mid-load, idling, and pre-injection performance.

EPS211 Common Rail Diesel Fuel Injector Testing Machine Advantage

Broad Compatibility: Supports both high-speed solenoid valve injectors and third-generation piezoelectric crystal injectors.

Precision Control: Features an intelligent PID algorithm for more precise pressure management and highly accurate output via synchronous belt transmission.

Enhanced Reliability: Built-in software and hardware short-circuit protection ensures machine longevity and safety.

User-Friendly Operation: Fully controlled by an industrial computer with multiple language options and a convenient interface.

Safety First: Includes a safety protection design to prevent operator error and protects against over-voltage and over-oil pressure.

Durable Build: The compact steel plate structure is shock-resistant and finished with a scratch-resistant electrostatic spray shell.

parameter

| Items | Parameter |

|---|---|

| Measuring Motor Speed | 0 ~ 3000 rpm |

| Oil Pump Speed | 0 ~ 1500 rpm |

| Working Pressure | 0 - 200 MPa |

| Fuel Tank Volume | 10 L |

| Test Oil Filtering Accuracy | 3μ |

| Oil Measuring Method | Flow meter / Graduated cylinder |

| Common Rail Pump Type | CP3 |

| Output Power | 4 KW (Motor: 2.6 KW) |

| Overall Dimensions | 830 * 750 * 900 mm |

| Net Weight | 160 Kg |

| Power Supply | 380V / 50HZ (Optional 220V) |

video

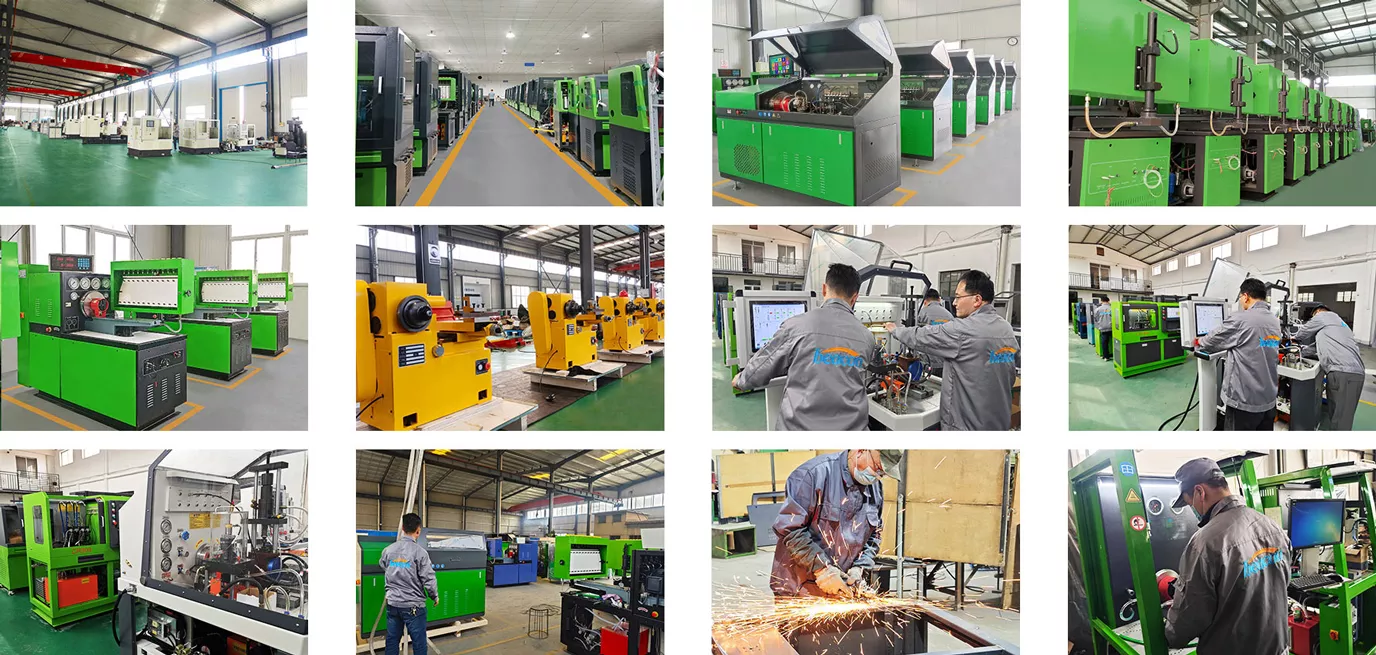

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language