DPF-RGA DPF Regeneration System Professional Diesel Particulate Filter Cleaning Machine

Details

The DPF Regeneration System and Test Bench is a comprehensive solution for maintaining Diesel Particulate Filters. It effectively removes accumulated carbon particles (soot) and ash through a high-pressure air purging process within a closed, vacuum-ventilated chamber. The system not only cleans but also verifies the cleaning effect by measuring the ventilation and back pressure, comparing results against a built-in database to ensure the DPF is restored to optimal working conditions.

DPF-RGA DPF Regeneration System Professional Diesel Particulate Filter Cleaning Machine Advantage

Closed Purge Chamber: Equipped with a vacuum fan and specialized filters to collect dust and soot, protecting the operator and the environment.

Back Pressure Testing: Includes a database software platform to compare pre- and post-regeneration pressure differences for guaranteed results.

All-Stainless Steel Pipeline: Prevents corrosion from humid environments, ensuring long-term durability and preventing secondary contamination.

User-Friendly Interface: Brightly lit cleaning room with an observation window and simple clamping structure for fast and reliable operation.

Data Traceability: Optional printer function to generate official test reports for customers.

Thorough Cleaning: Combines high-pressure air blowing with effective dust extraction to remove even deep-seated ash.

parameter

| Item | Specification |

|---|---|

| Product Name | DPF Regeneration System & Test Bench |

| Cleaning Method | High-pressure Air Purging & Vacuum Extraction |

| Material | Industrial Grade Stainless Steel |

| Control System | Database Software Platform (Customizable) |

| Main Features | Back Pressure Test, Dust Collection, Data Logging |

| Safety Design | Closed Purge Chamber with Observation Window |

| Optional Function | Thermal Paper Printer for Test Reports |

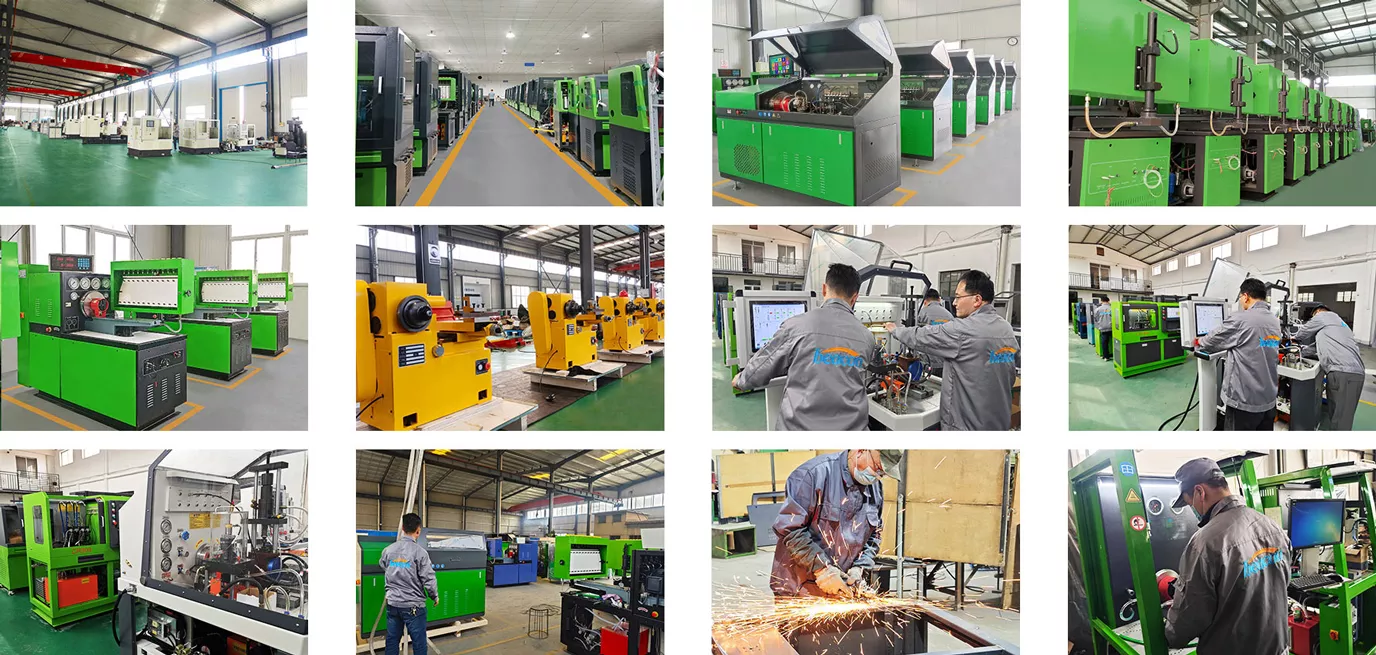

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language