DPF-CL MINI FUEL Intelligent DPF Regeneration Machine Portable Thermal Cleaning System

Details

The DPF-CL (MINI FUEL) is an intelligent post-treatment regeneration device designed to simulate vehicle regeneration processes. By outputting continuous thermal energy (up to 1000°C) directly to the filter's core, it effectively carbonizes and removes deposits without damaging the insulation layer. This fuel-powered version is highly efficient, capable of rapid heating and cooling, ensuring a regeneration completion rate of over 96%.

DPF-CL MINI FUEL Intelligent DPF Regeneration Machine Portable Thermal Cleaning System Advantage

High Efficiency: Achieves a regeneration completion rate of ≥96% through high-temperature carbonization.

Rapid Performance: Heats from 0°C to 1000°C in just 4 minutes and cools down to 50°C in 10 minutes.

Intelligent PLC Control: Features a high-definition touch screen with PID temperature control for precise multi-stage settings.

Superior Durability: Internal components are made of 310S high-temperature resistant stainless steel, withstands up to 1300°C.

Energy Saving: Optimized thermal output makes it 50% more energy-efficient than traditional electric heating methods.

Safety Features: Equipped with a back pressure alarm system and an "explosive blowing" function to clear residues safely.

parameter

| Item | Specification |

|---|---|

| Model | DPF-CL (MINI FUEL) |

| Max Temperature | 1000 °C |

| Heating Speed | 0°C to 1000°C in 4 mins |

| Cooling Speed | 1000°C to 50°C in 10 mins |

| Regeneration Rate | ≥ 96% |

| Fuel Type | Diesel |

| Internal Material | 310S Stainless Steel |

| Control System | PLC / PID Touch Screen |

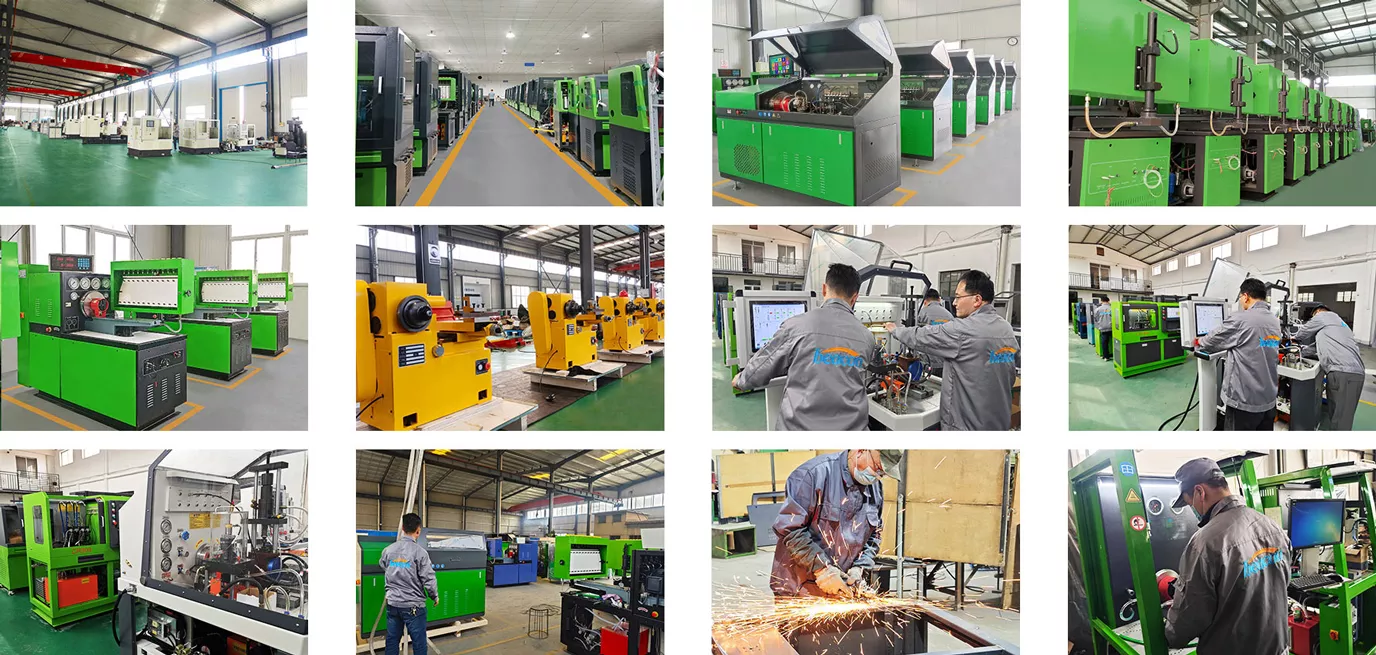

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language