CRM3000 Professional Common Rail Injector Repair Measuring System for Bosch Denso Delphi CAT

Details

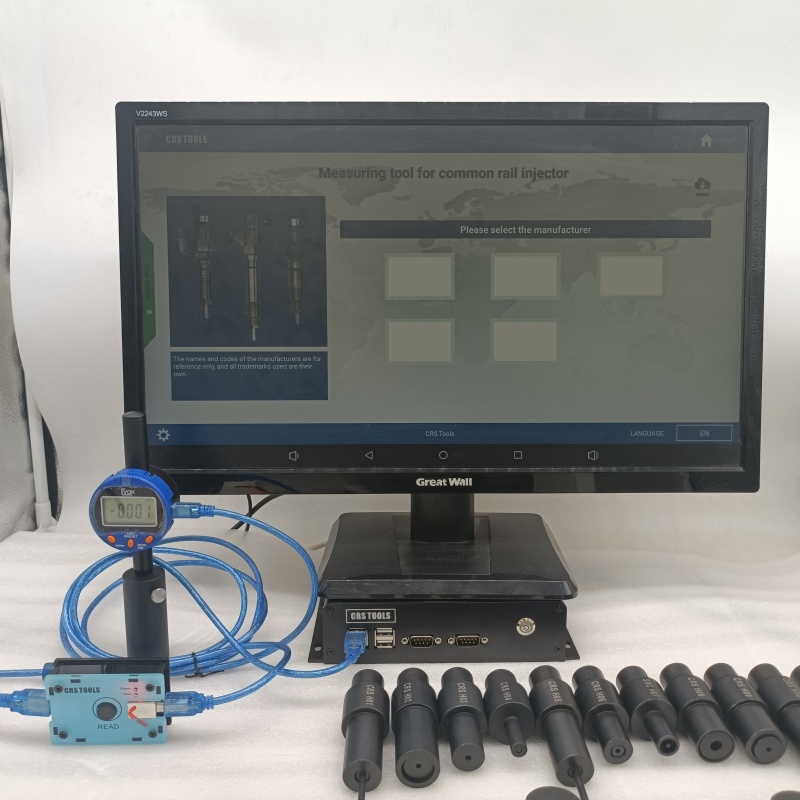

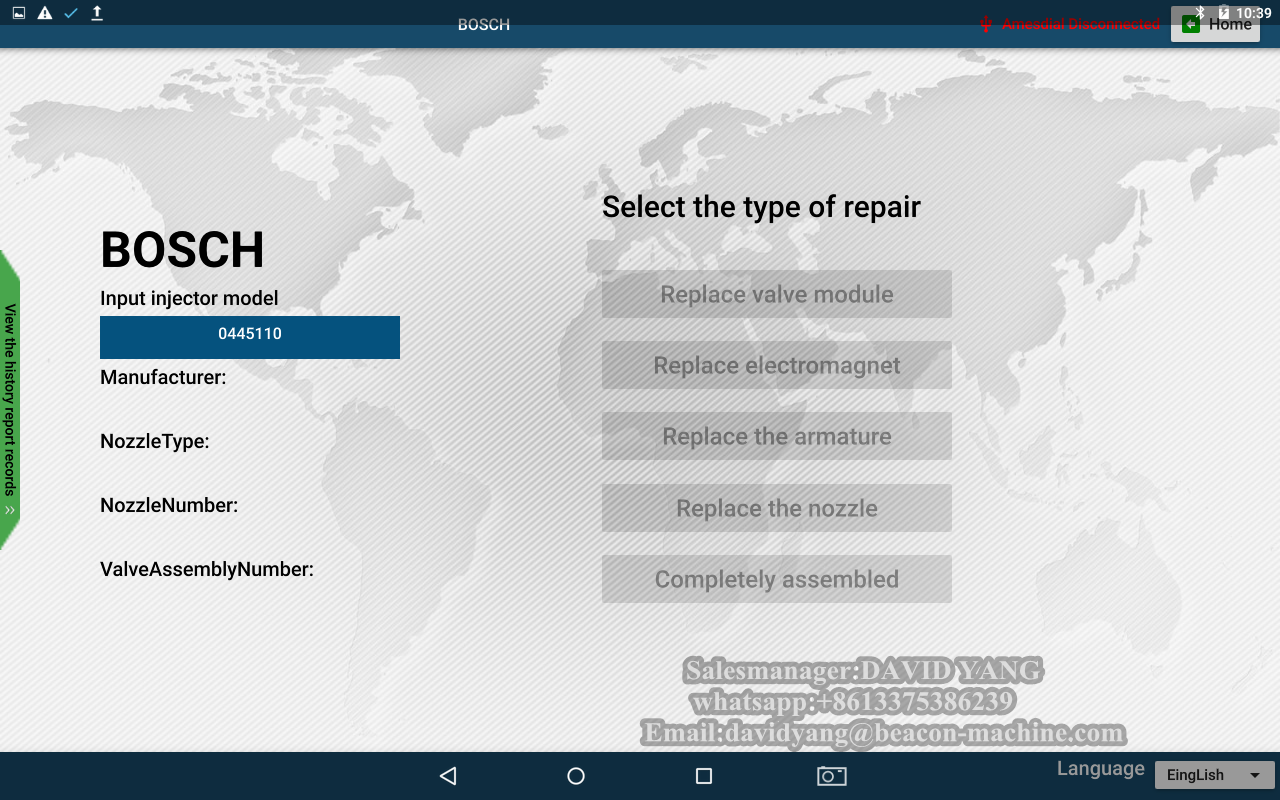

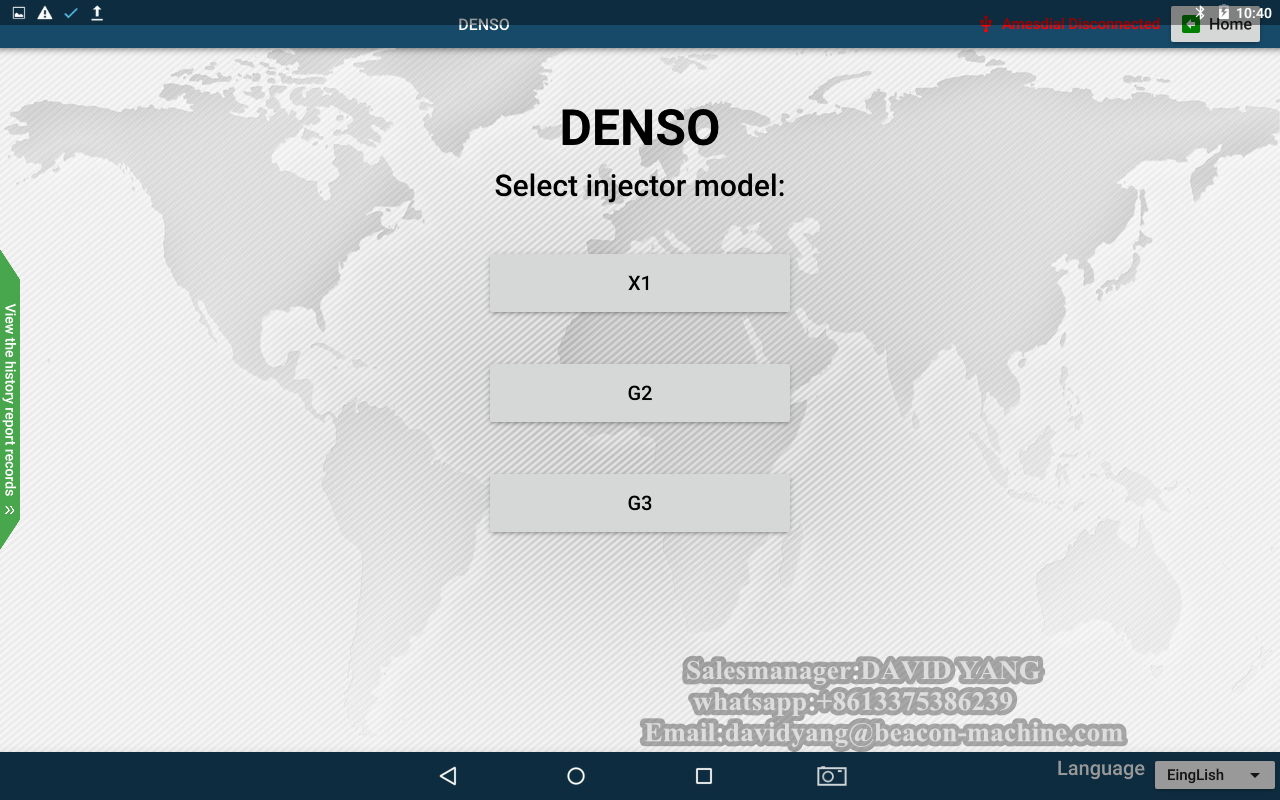

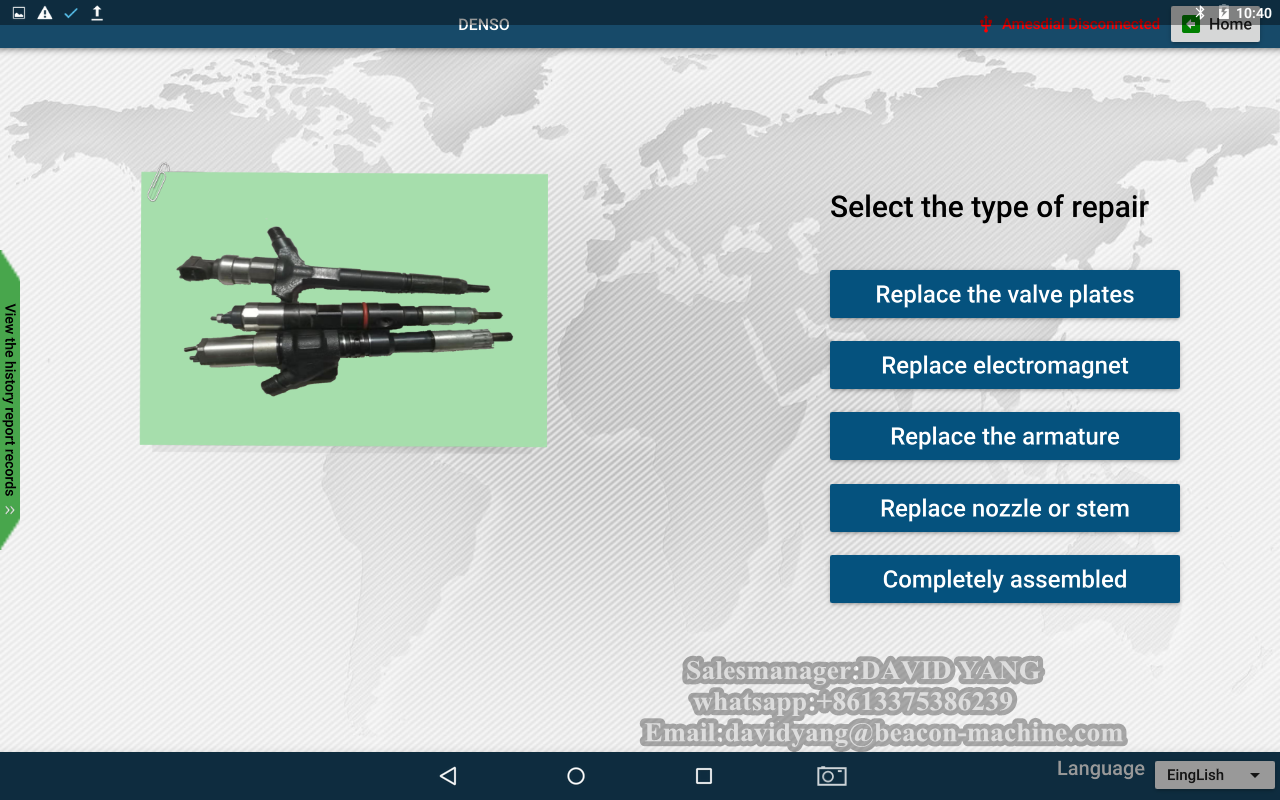

The CRM3000 Common Rail Injector Repair Measuring System is an essential diagnostic and maintenance assistant for diesel technicians. It integrates an extensive database of maintenance standard data for world-leading brands such as Bosch, Denso, Delphi, Carter (CAT), and Siemens.

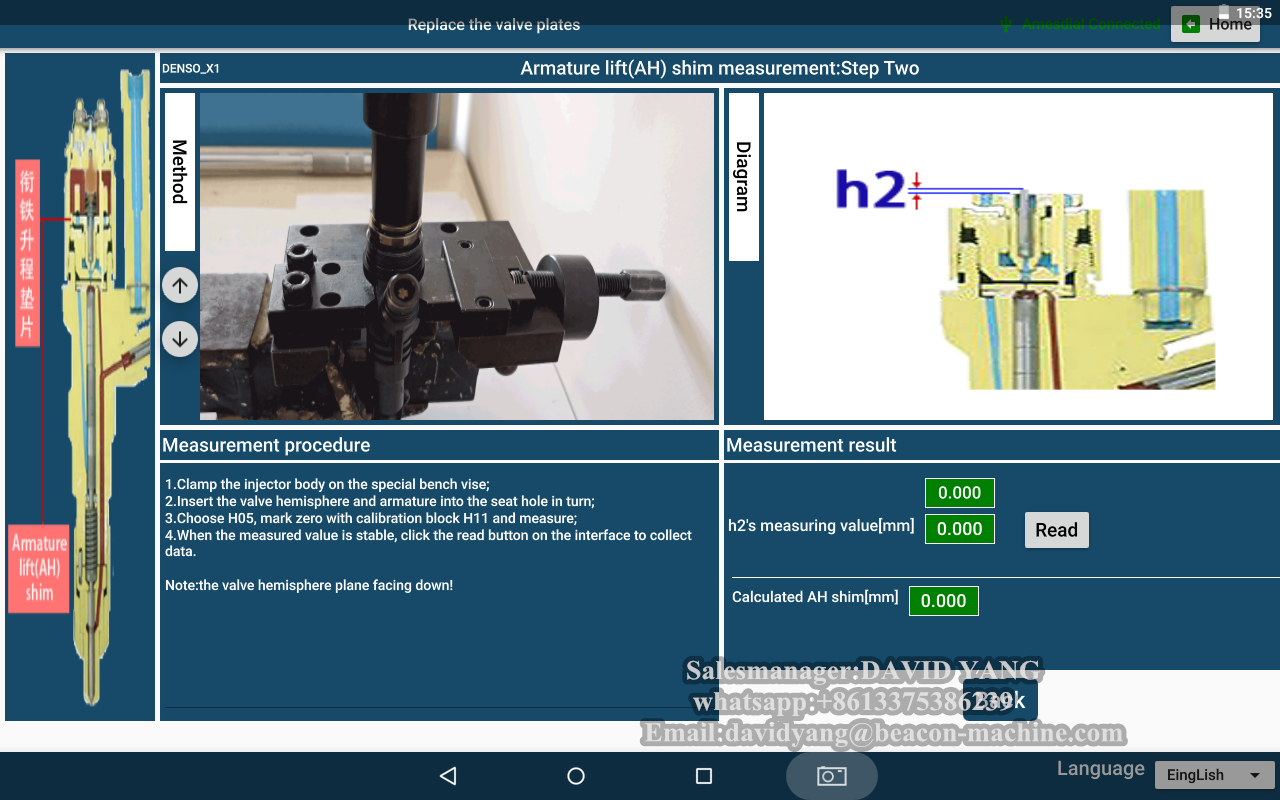

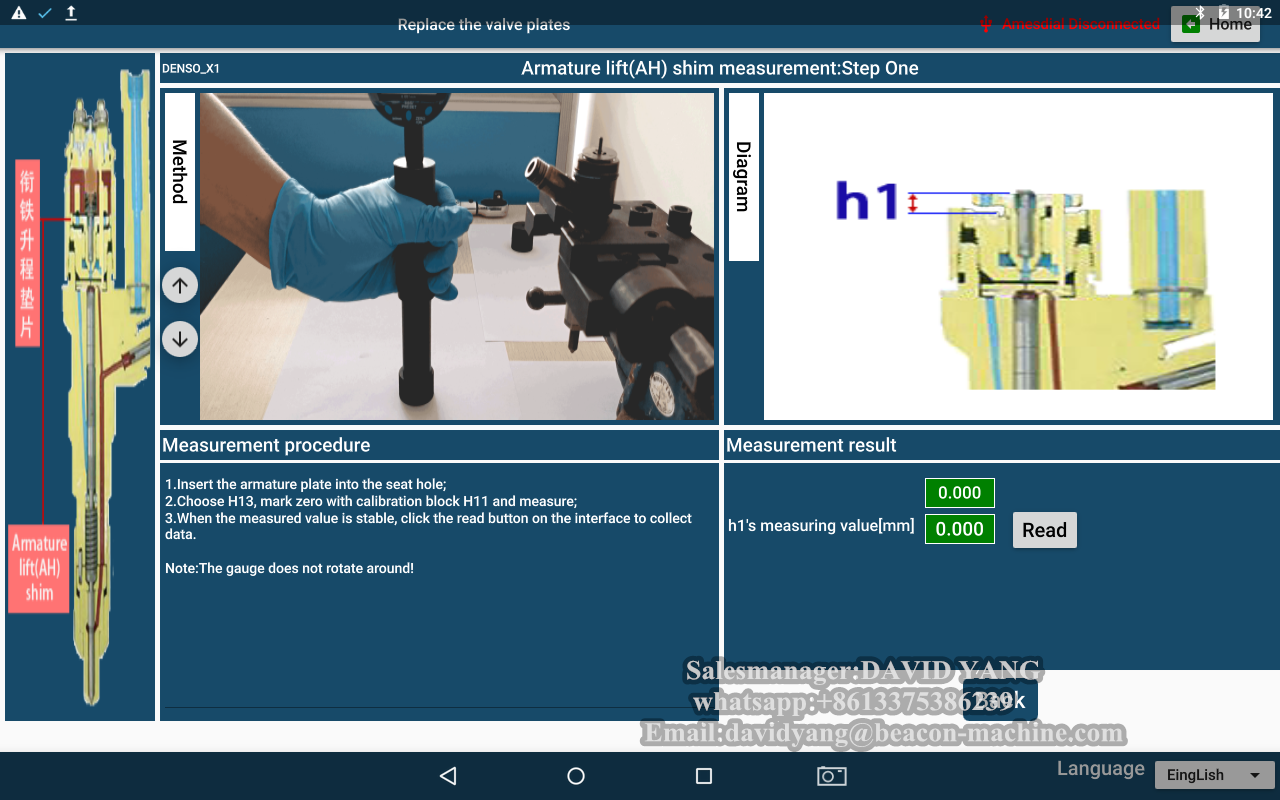

Designed to simplify the complex process of injector reconditioning, the CRM3000 guides users through critical measurement steps, including armature lift and valve assembly shim selection. With its high-precision digital gauges and intuitive software interface, it allows for fast data collection and history report viewing, ensuring every repaired injector meets OEM performance standards

CRM3000 Professional Common Rail Injector Repair Measuring System for Bosch Denso Delphi CAT Advantage

Comprehensive Database: Pre-loaded with standard calibration data for Bosch, Denso, Delphi, CAT, and Siemens injectors.

High-Precision Measurement: Features digital dial indicators with zero-calibration functions for micron-level accuracy.

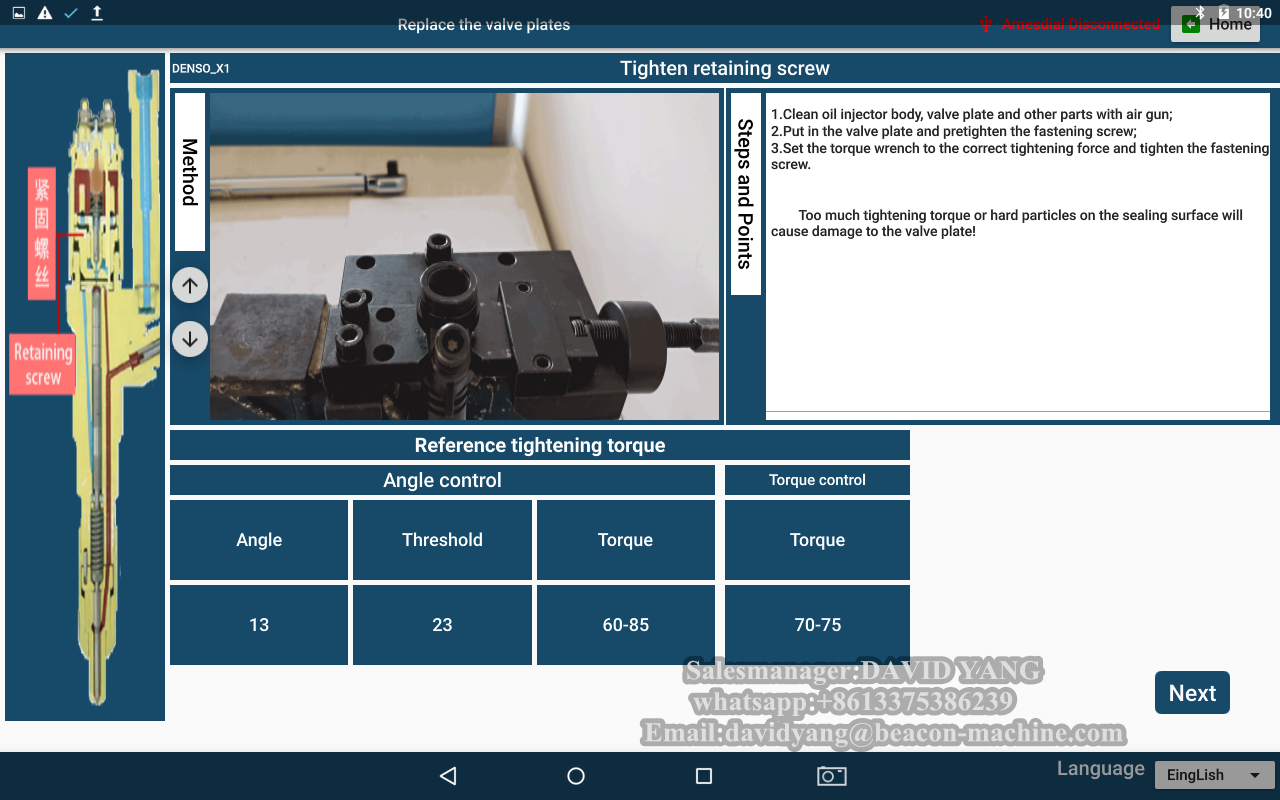

Step-by-Step Guidance: Visual software instructions for replacing valve plates, electromagnets, nozzles, and measuring armature lifts.

Smart Data Collection: One-click "Read" button to capture stable measurement values and automatically calculate results.

Torque Control Reference: Provides precise tightening torque and angle control standards for various injector types.

History Management: Easily view and manage historical measurement reports for quality control and customer records.

parameter

| Technical Items | Specifications (CRM3000) |

|---|---|

| Supported Brands | Bosch, Denso, Delphi, CAT, Siemens, Great Wall |

| Measurement Types | Armature Lift, Valve Shim, Nozzle/Stem Travel, Solenoid Gap |

| Data Interface | High-precision Digital Display with PC Connection |

| Language Support | English, Chinese, etc. |

| Torque Control | 60-85 Nm (Standard Reference) |

| Zero Calibration | Standard Calibration Block (H11) included |

| Key Components | Measuring Console, Digital Gauge, Multi-functional Fixtures |

| Special Function | Automatic calculation of shim thickness & History reporting |

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language