CR708 Diesel Fuel Common Rail Injector and Common Rail Pump Test Bench

Details

The CR708 is a multi-functional diesel fuel injection system test bench designed for high-performance diagnostics. It is powered by a high-stability industrial computer and a Windows operating system, ensuring precise control over the testing environment. This versatile machine is capable of testing a wide range of components including Common Rail injectors (Bosch, Denso, Delphi, Siemens), pumps (CP1, CP2, CP3, HP0), EUI/EUP systems, and HEUI systems. Equipped with a Bosch CP3 pump and 2400 bar rail pressure capacity, it represents the gold standard for modern diesel service centers.

CR708 Diesel Fuel Common Rail Injector and Common Rail Pump Test Bench Advantage

Multi-System Compatibility: Tests Common Rail injectors, high-pressure pumps, EUI/EUP, and HEUI systems in one unit.

High-Pressure Performance: Adopts the original Bosch CP3 pump and high-precision sensors to provide rail pressure from 0 to 2400 bar.

Intelligent Operation: Managed by a Windows-based industrial PC with a 19-inch LCD screen for real-time monitoring and data management.

Comprehensive Database: Features a searchable database for thousands of injector and pump part numbers.

Precision Measurement: Utilizes high-precision flow sensors to ensure accurate oil quantity measurement for all test phases.

Professional Coding: Supports injector coding for Bosch, Denso, Delphi, and Siemens, including QR and IMA coding.

Safety & Stability: Built with high-pressure protection and short-circuit protection for reliable, low-noise operation.

parameter

| Technical Parameter | Specification |

|---|---|

| Output Power | 11KW / 15KW / 18.5KW / 22KW |

| Power Voltage | 380V / 220V 3-phase |

| Motor Speed Range | 0 - 4000 RPM |

| Rail Pressure Range | 0 - 2400 Bar |

| Flow Measurement Range | 0 - 600 ml/1000 times |

| Temperature Control Range | 40 ± 2°C |

| Oil Tank Volume | 80 Liters |

| Overall Dimension | 2100 * 1100 * 1750 MM |

| Net Weight | 1100 KG |

video

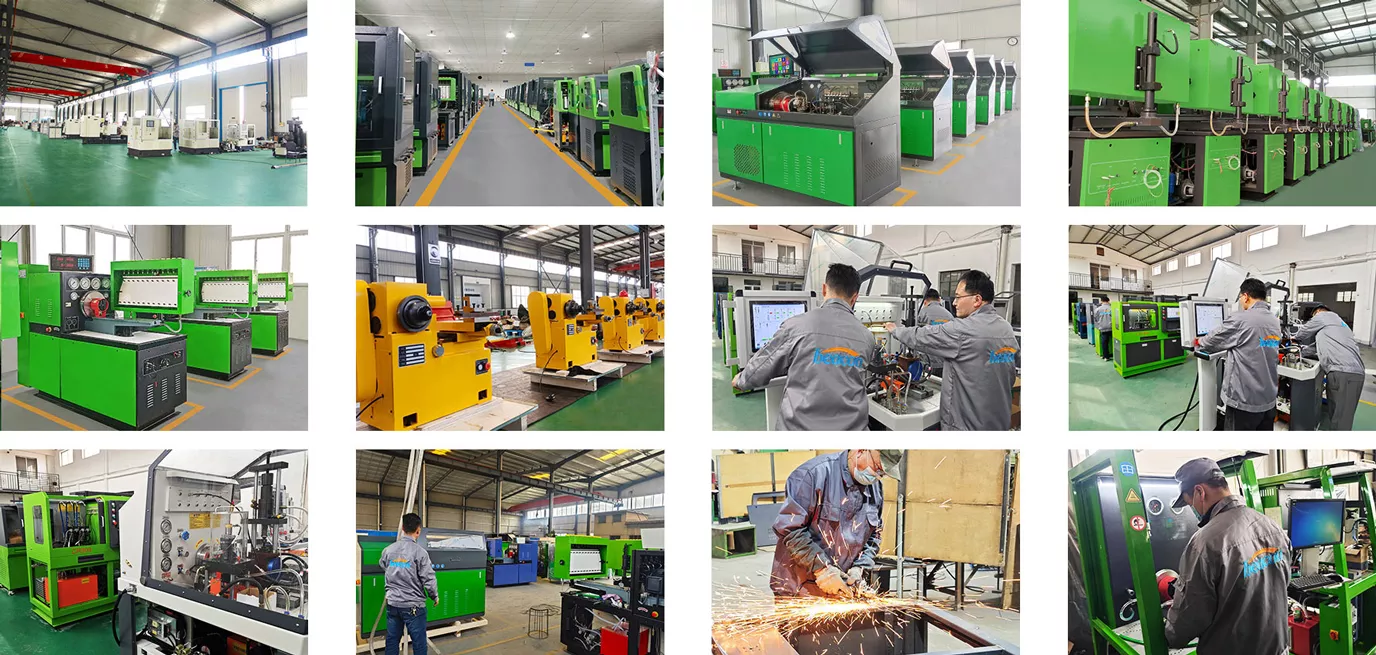

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language