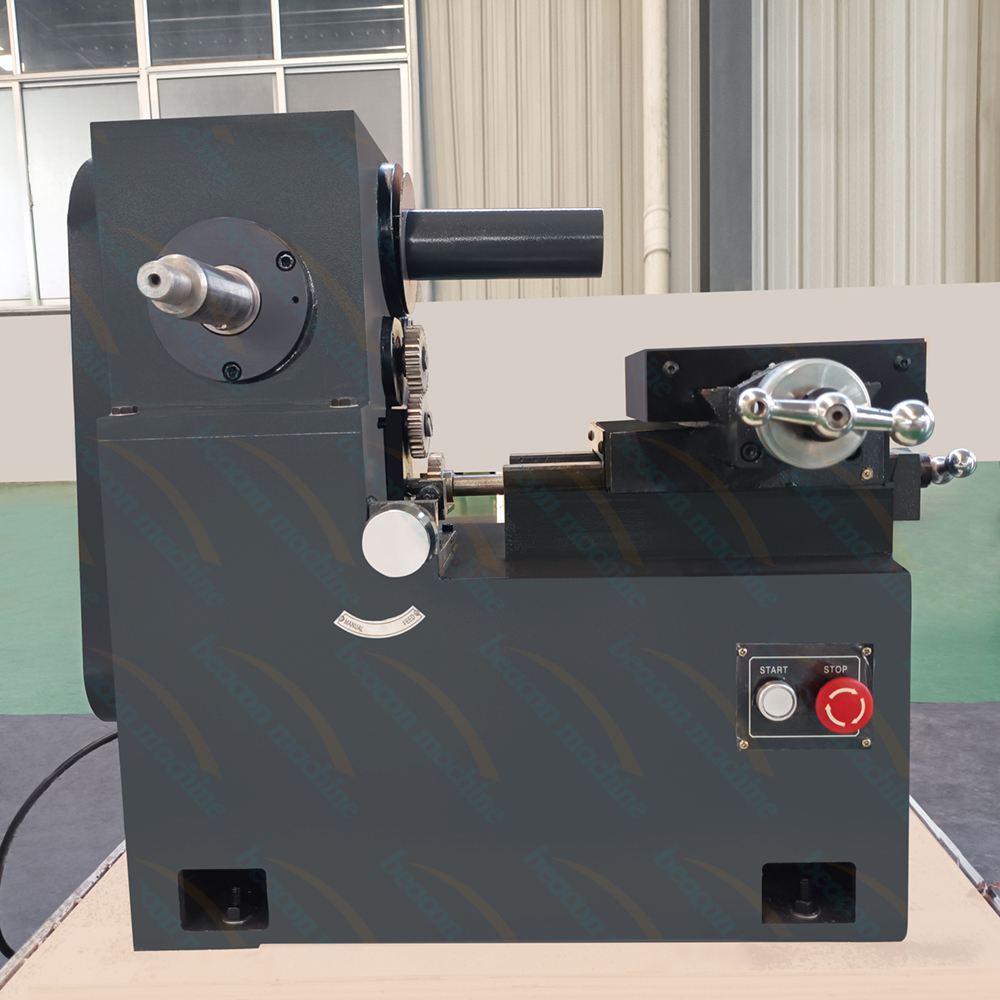

C9335 Brake Drum Disc Cutting Lathe Brake Drum Repair Machine

Details

The C9335A Brake Drum and Disc Lathe is a versatile and high-precision machine designed for resurfacing brake components of various small vehicles. This equipment allows for the direct connection of the lathe to the brake disc or drum using wheel screws, ensuring convenient installation and exceptional processing accuracy.

Equipped with a professional three-phase asynchronous motor and a heavy-duty machine frame, the C9335A maintains stability during high-speed operations. Its optimized double-knife structure allows for simultaneous or separate processing, making it an essential tool for automotive service centers focusing on brake system maintenance.

C9335 Brake Drum Disc Cutting Lathe Brake Drum Repair Machine Advantage

High Precision Auto-Feeding: Utilizes an oil-free, self-lubricating, wear-resistant stainless steel ball screw for smooth and accurate cutter movement.

Powerful Performance: Adopts a professional 750W/1.1KW motor for high efficiency and reliability.

Vibration-Free Operation: The heavy machine frame (up to 200kg gross weight) ensures stability even during long-term high-speed milling.

Optimized Double-Knife Design: Features a dual-cutter structure that makes adjusting the feed amount more convenient and faster.

Strong Rigidity: Built with high-rigidity cutters to achieve rapid milling and superior surface finish.

Flexible Mobility: The base can be equipped with universal wheels, allowing the machine to be moved easily within the workshop.

parameter

| Items | Specifications (C9335A) |

|---|---|

| Processing Range (Brake Drum) | 180 - 350 mm |

| Processing Range (Brake Disc) | 180 - 350 mm |

| Rotating Speed of Workpiece | 75 / 130 r/min |

| Max. Travel of Tool | 100 mm |

| Feeding Capacity | 0.15 mm/r |

| Motor Power | 1.1 KW (Standard) / 750W |

| Net Weight / Gross Weight | 200 kg / 230 kg |

| Application | Repair of small vehicle braking drums/disks |

video

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language