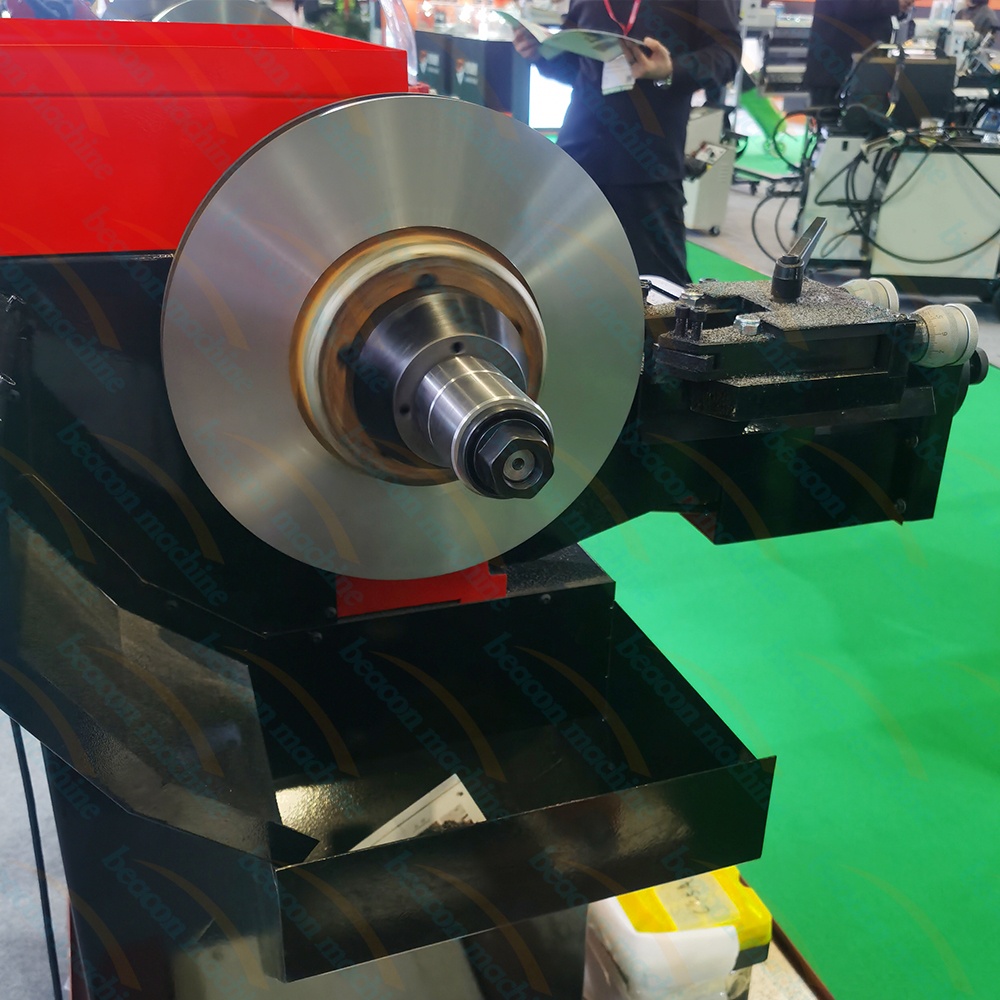

C45A Professional Brake Disk Lathe Machine for Dual-Face Precision Resurfacing

Details

The C45A Brake Disk Lathe is a high-efficiency precision machine specifically developed for the maintenance of brake disks on medium and small-sized vehicles. Its most significant feature is the ability to turn both faces of a brake disk simultaneously, which greatly improves work efficiency and ensures parallelism between the two surfaces.

Equipped with a high-precision linear slideway, the C45A guarantees smooth movement and superior surface finish. The machine also features a variable feeding speed system and an optimized tool post, making it incredibly user-friendly and adaptable to various repair requirements in modern automotive workshops.

C45A Professional Brake Disk Lathe Machine for Dual-Face Precision Resurfacing Advantage

Dual-Face Turning: Simultaneously machines both sides of the brake disk to ensure perfect alignment and save operation time.

High-Precision Slideway: Features a professional linear slideway that ensures exceptional turning precision and stability.

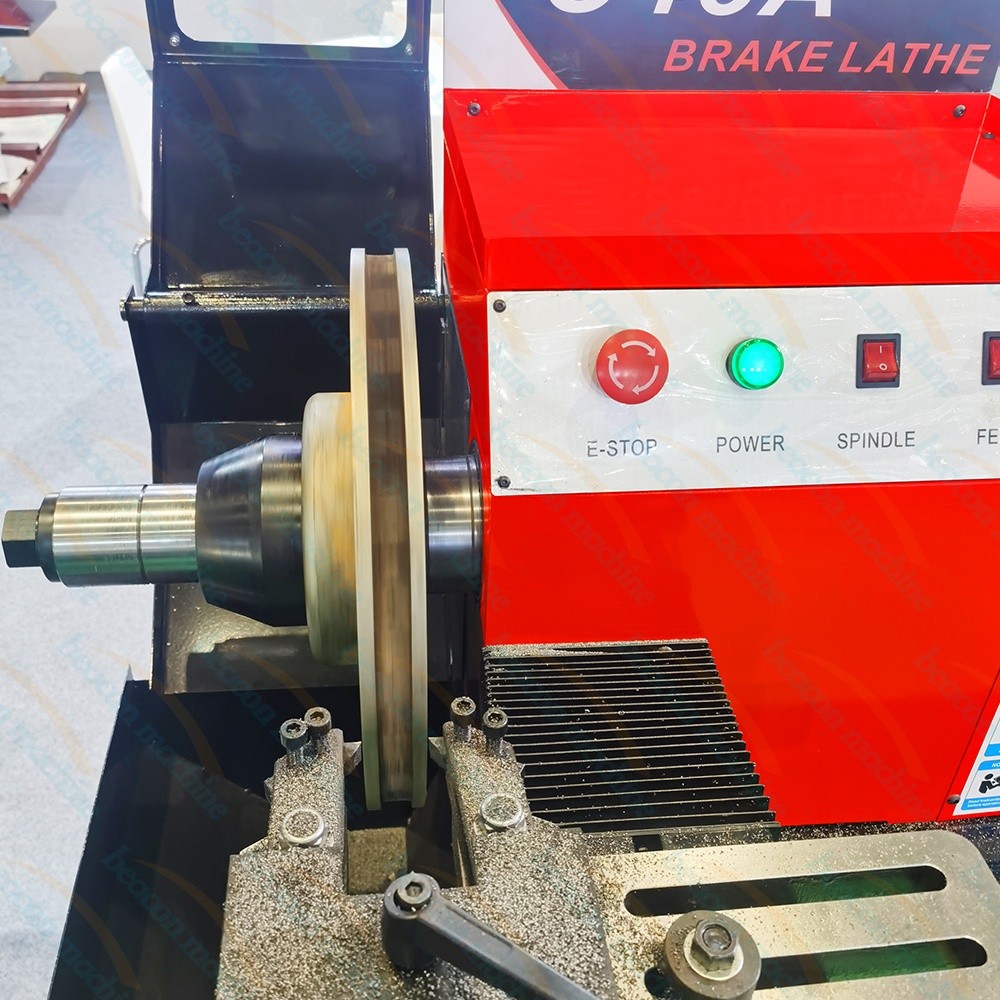

Variable Feeding Speed: Adjustable feed rates allow for customized control based on the disk material and required finish quality.

Optimized Tool Post: Designed for more convenient and intuitive operation, reducing the learning curve for technicians.

Integrated Storage: The base is equipped with drawers for convenient storage of tools and accessories.

Safety First: Includes an easy-access Emergency Stop (E-STOP) button and clear power indicators for safe operation.

parameter

| Technical Items | Specifications (C45A) |

|---|---|

| Model | C45A |

| Range of Processing Diameter | 180 - 450 mm |

| Rotating Speed of Workpiece | 120 r/min |

| Feeding Capacity | 0 - 0.66 mm/r (Variable) |

| Motor Power | 0.75 kw |

| Machine Weight | 240 kg |

| Key Features | Linear slideway, Dual-face turning, Base with drawers |

video

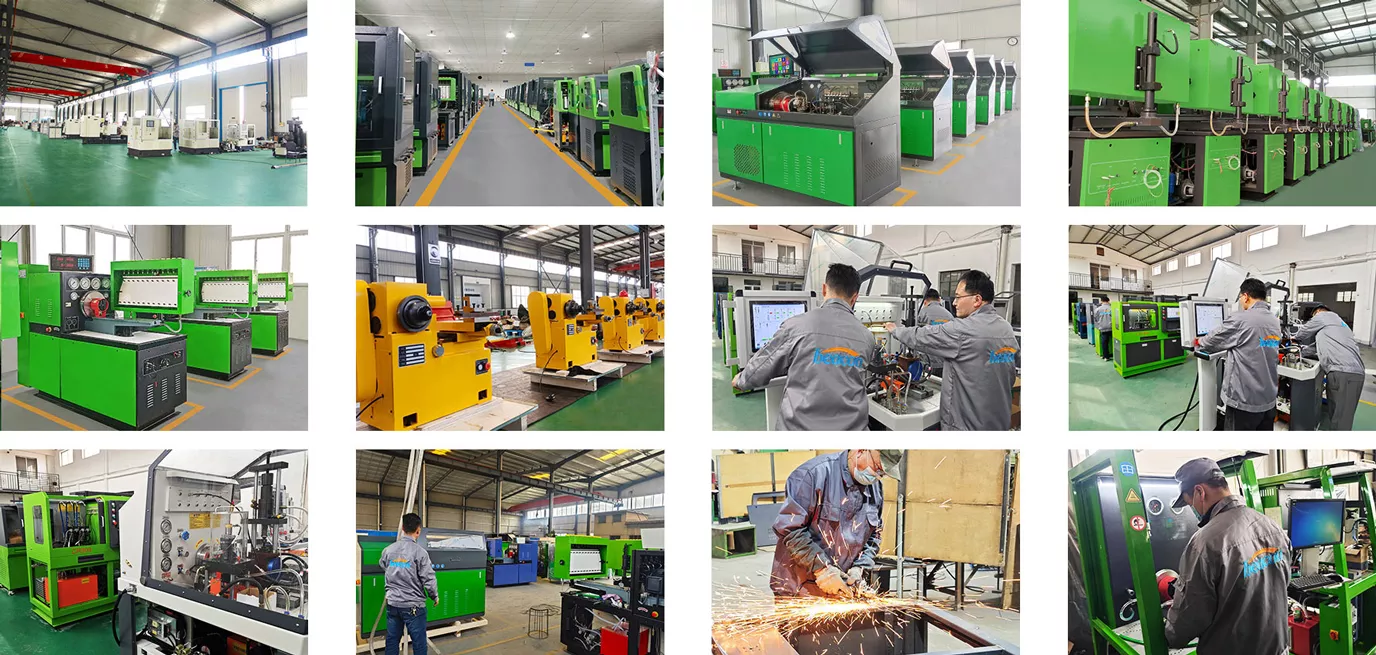

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language