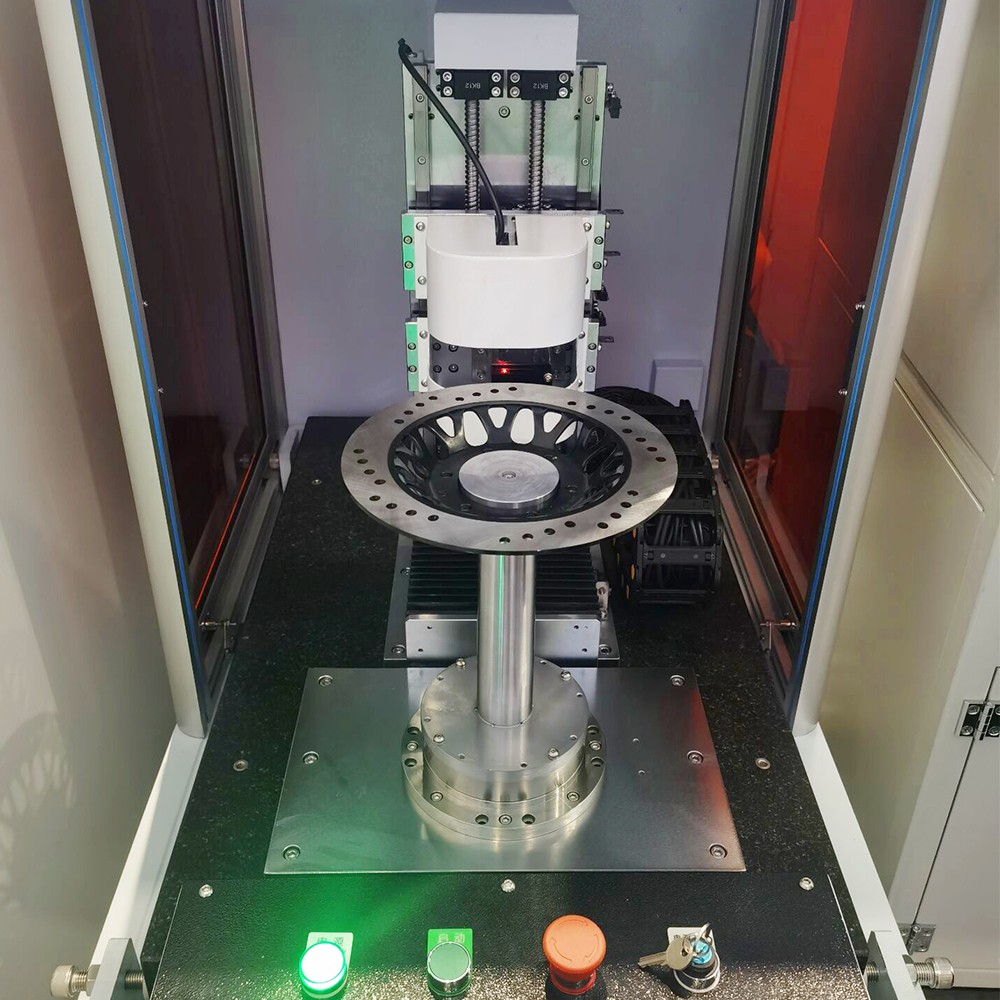

BD101 Semi-automatic Brake Disc Laser Testing Machine for High-Precision Dimension Measurement

Details

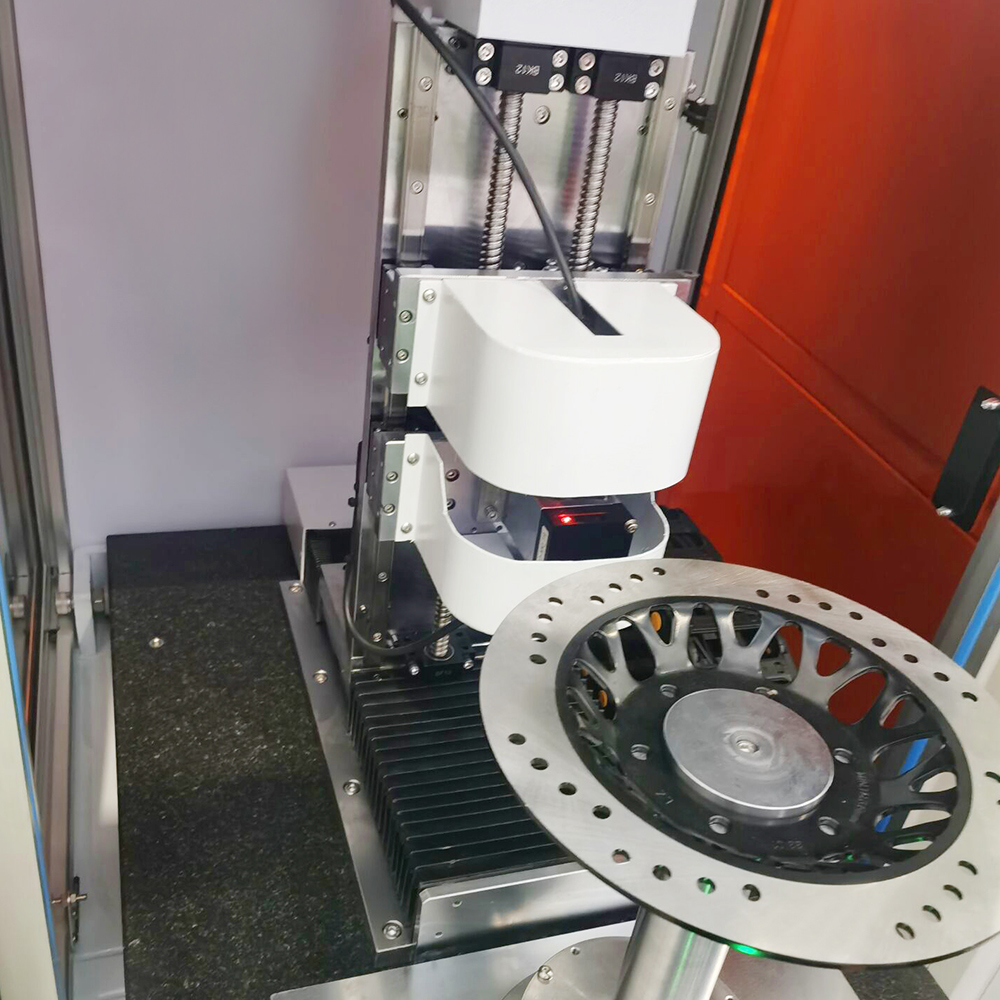

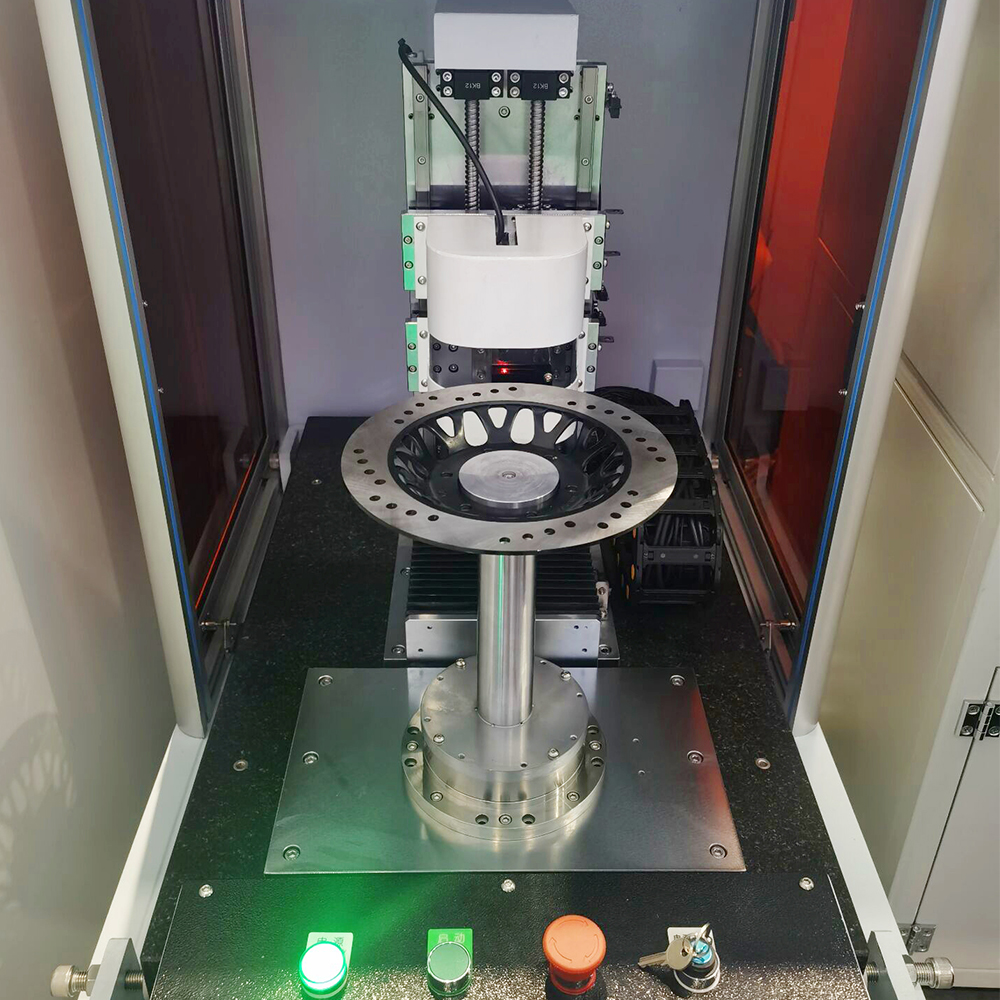

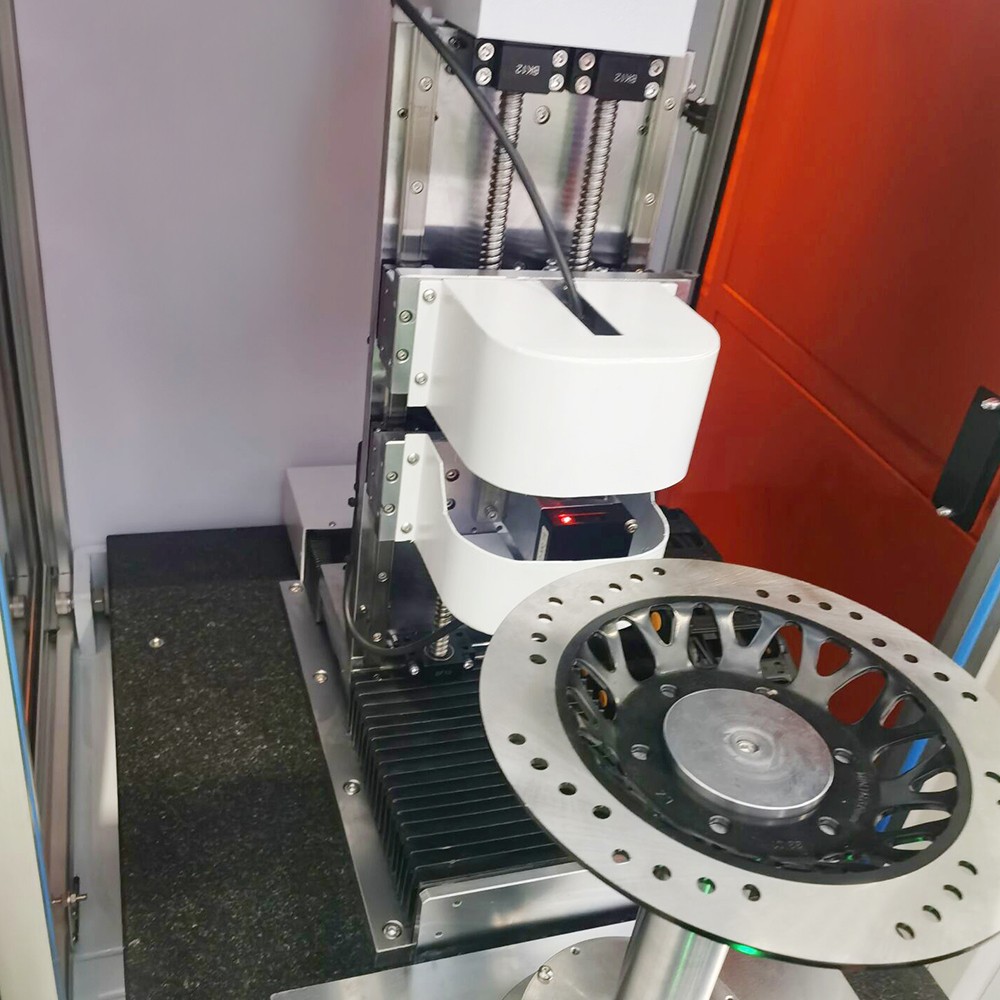

The BD101 Brake Disc Laser Semi-automatic Testing Machine is a high-tech diagnostic tool designed for the precision measurement of automotive brake rotors. It utilizes advanced laser displacement sensors to perform non-contact sampling, allowing for the rapid evaluation of critical geometric parameters.

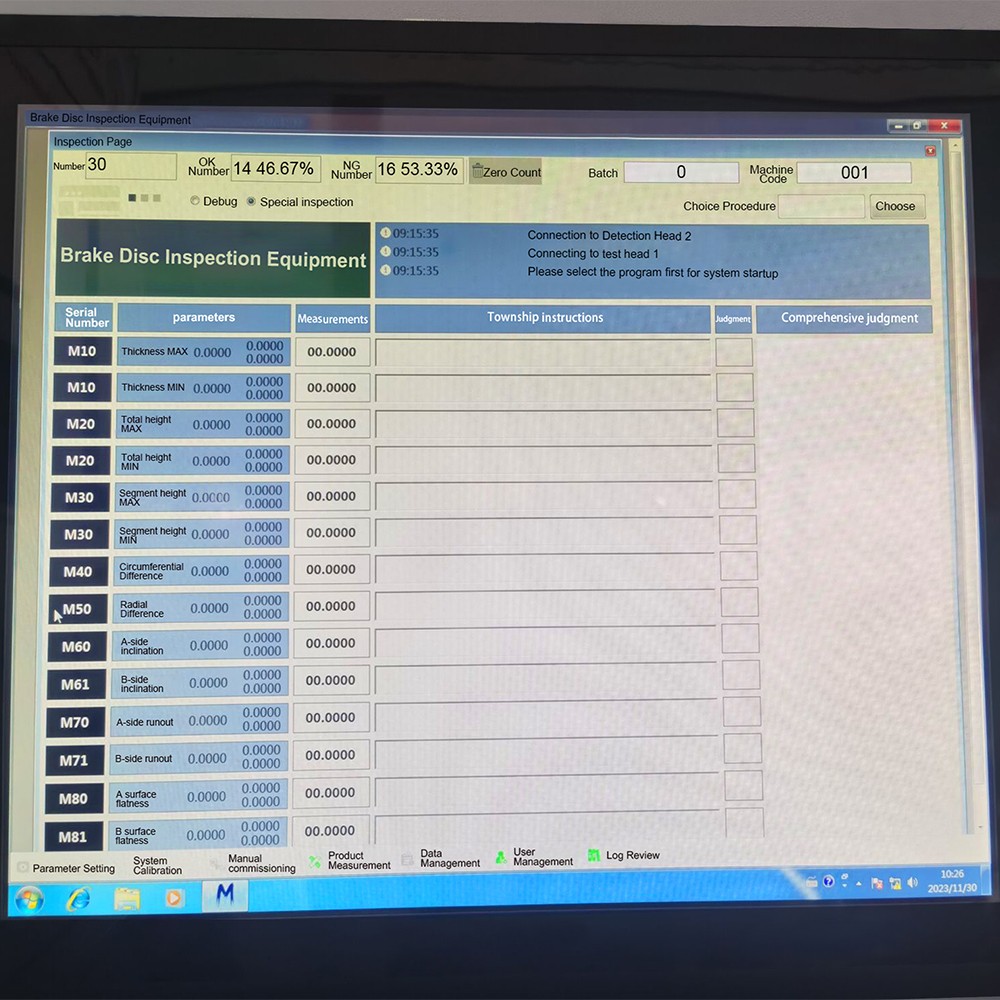

The system is powered by a Taiwan Advantech industrial control computer and features specialized software that automatically removes groove data from intermittent surfaces to ensure measurement purity. With a cycle time of less than 10 seconds per piece, the BD101 provides a fast, reliable, and highly accurate alternative to manual testing in machining workshops.

BD101 Semi-automatic Brake Disc Laser Testing Machine for High-Precision Dimension Measurement Advantage

High Precision Laser Sensing: Equipped with dual laser sensors achieving a repetitive measurement accuracy of ±0.0015mm for thickness and DTV.

Rapid Cycle Time: Completes a full two-week rhythm measurement in less than 10 seconds per piece, significantly boosting productivity.

Comprehensive Detection: Measures multiple parameters including plate thickness, flatness, runout (upper/lower), total height, and radial/circumferential DTV.

Intelligent Data Management: The built-in software automatically saves results, calculates defect rates, and generates composite ratio data for quality analysis.

Smart Surface Evaluation: Advanced algorithms automatically filter out grooves and surface interruptions to evaluate only the functional disc area.

Flexible Product Switching: Easily adjustable sensor heights and replaceable positioning tables allow for quick switching between different disc specifications.

parameter

| Technical Items | Specifications (BD101) |

|---|---|

| Workpiece Diameter Range | Φ 100 ~ Φ 340 mm |

| Workpiece Thickness / Height | 1.5-10mm (Thickness) / < 35mm (Total Height) |

| Max Workpiece Weight | 12 Kg |

| Measurement Accuracy (Thickness) | ± 0.0015 mm |

| Geometric Tolerance Accuracy | ± 0.003 mm |

| Measurement Cycle Time | < 10 seconds per piece |

| Control System | Advantech Industrial PC (I/O & Motion Control) |

| Power Supply | AC 220V ± 10% |

| Gas Source Requirement | 0.5 - 0.7 Mpa |

| Equipment Dimensions | Approx. 0.8m x 1.0m x 2.1m (LxWxH) |

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language