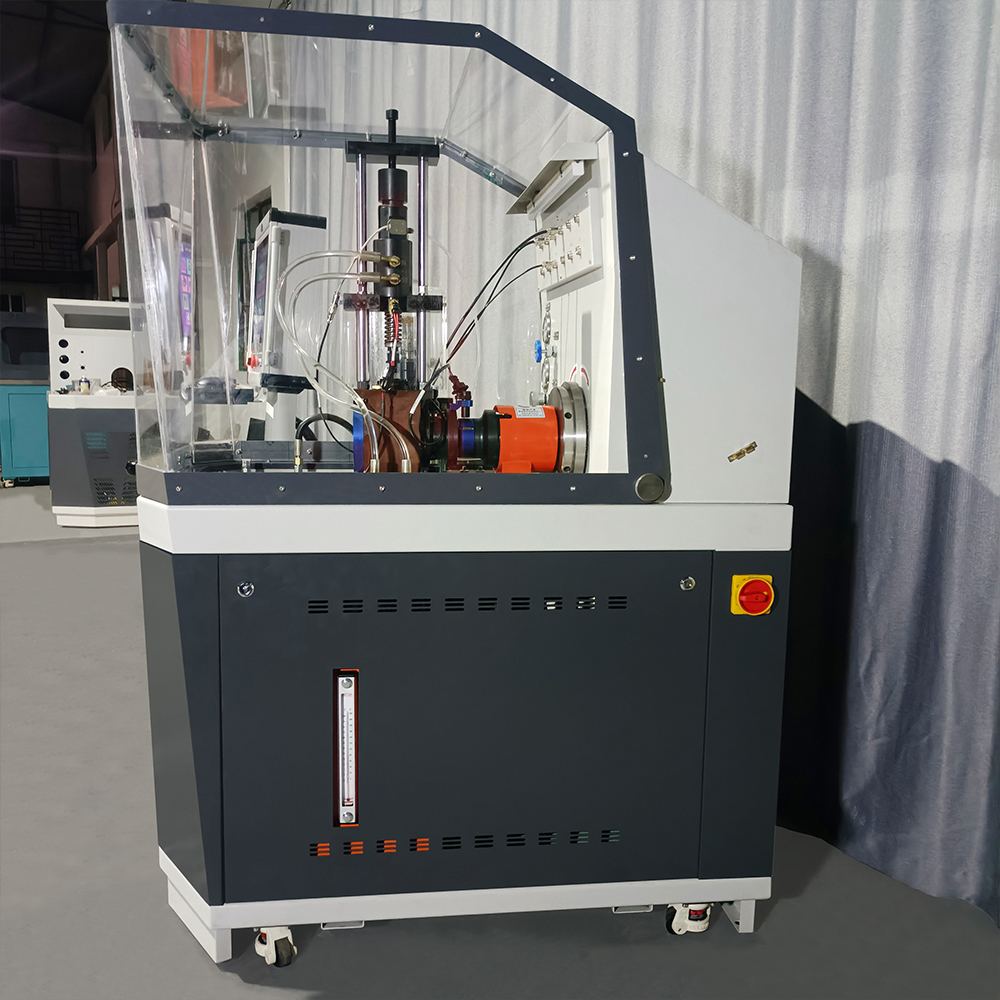

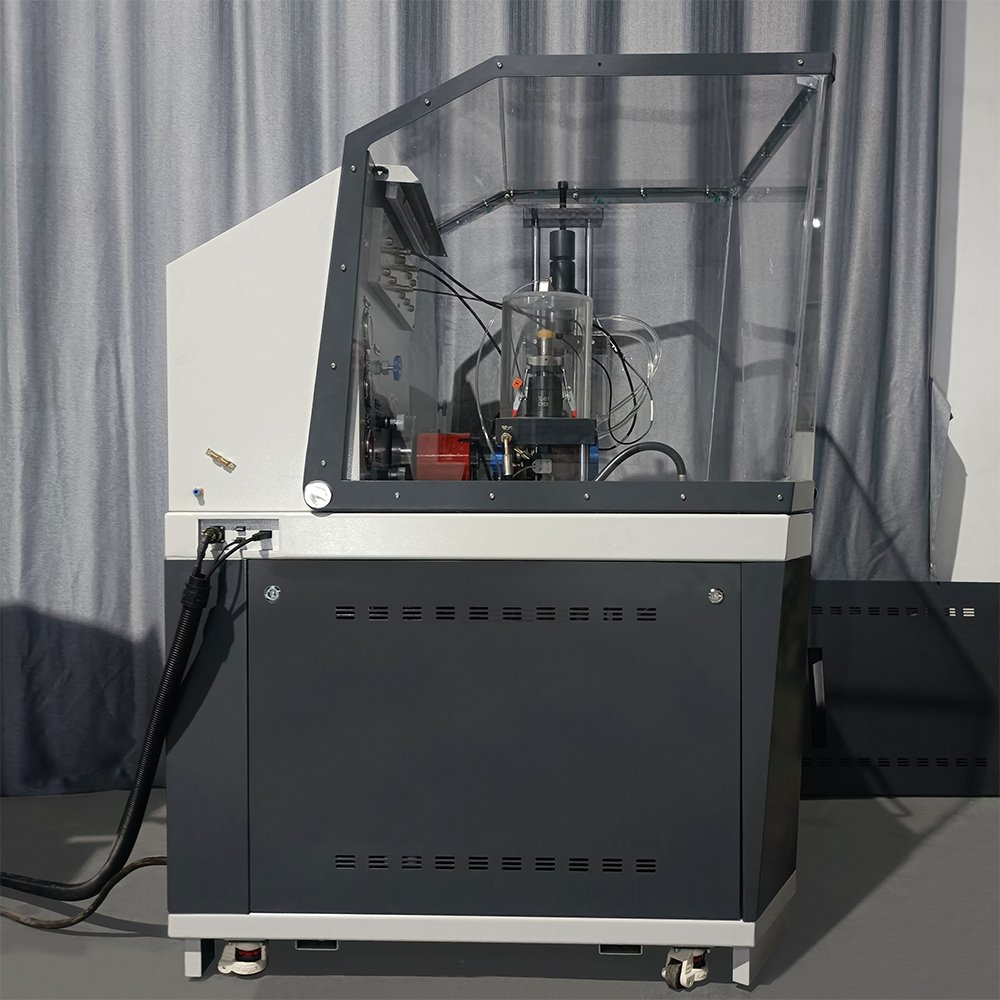

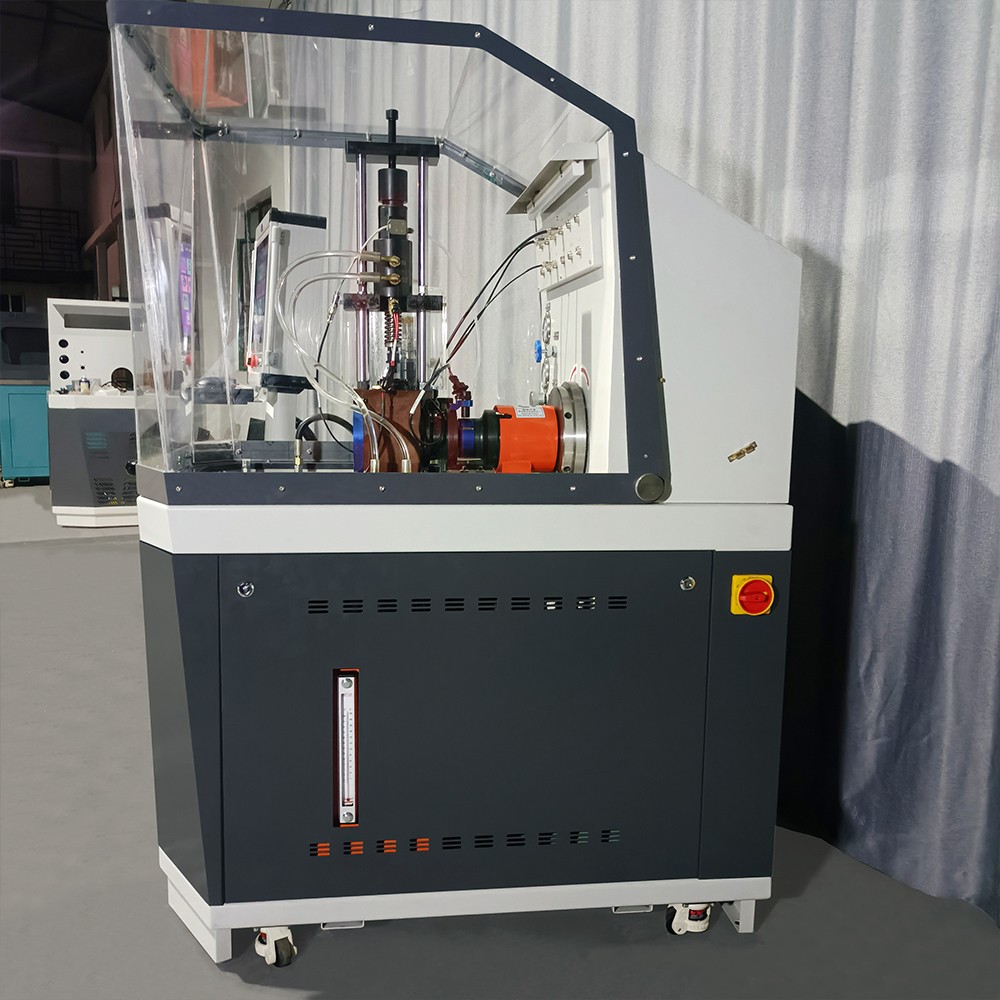

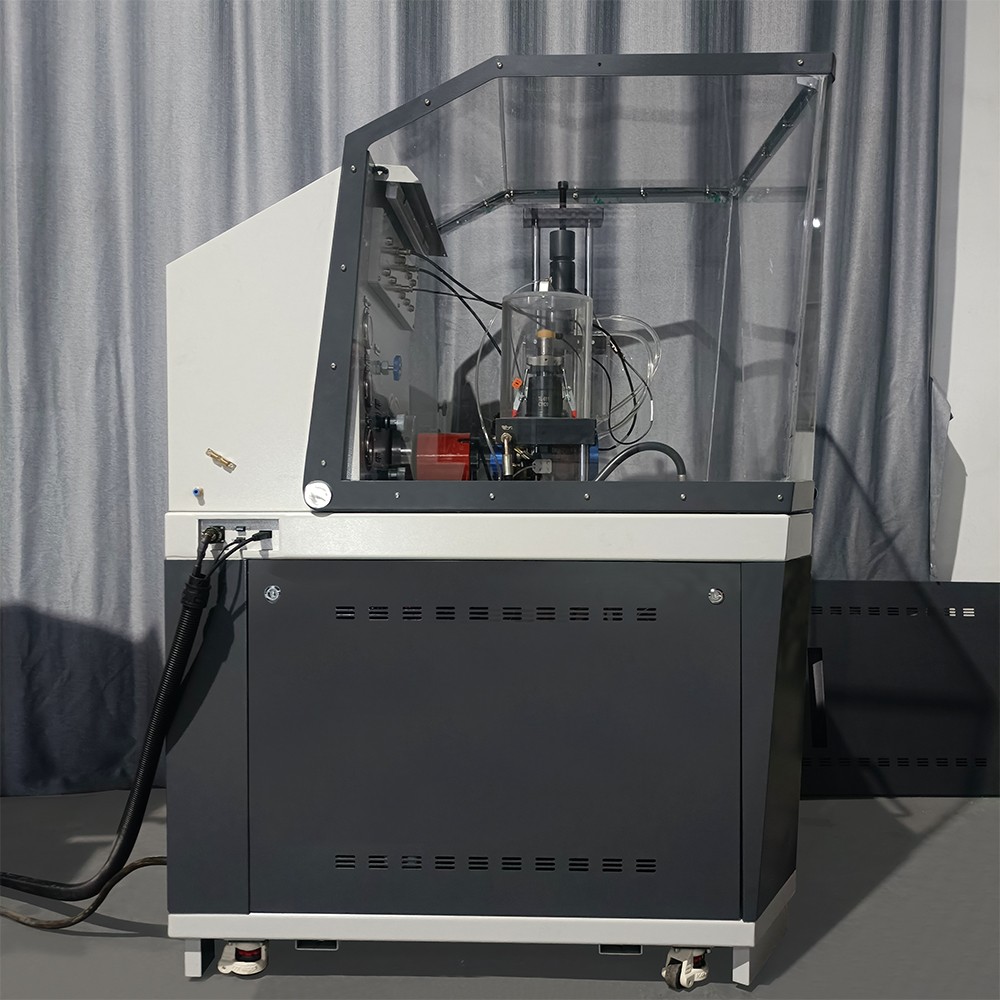

BC808 HEUI EUI EUP Common Rail Injector Pump All In One Test Bench

Details

The BC808 Comprehensive Test Bench is an all-in-one diagnostic solution designed for the maintenance of advanced electronic diesel systems. It utilizes a fully automatic control system to test a wide range of components, including common rail injectors (including piezoelectric), high-pressure common rail pumps, EUI/EUP (Electronic Unit Pumps/Injectors), and HEUI systems.

Equipped with an industrial computer and a massive database covering thousands of models from brands like Bosch, Denso, Delphi, Siemens, Caterpillar, and Cummins, the BC808 provides precise measurements for sealing, full load, fuel return, and idling performance. Its versatile design and high-accuracy sensors make it an essential tool for professional diesel service centers.

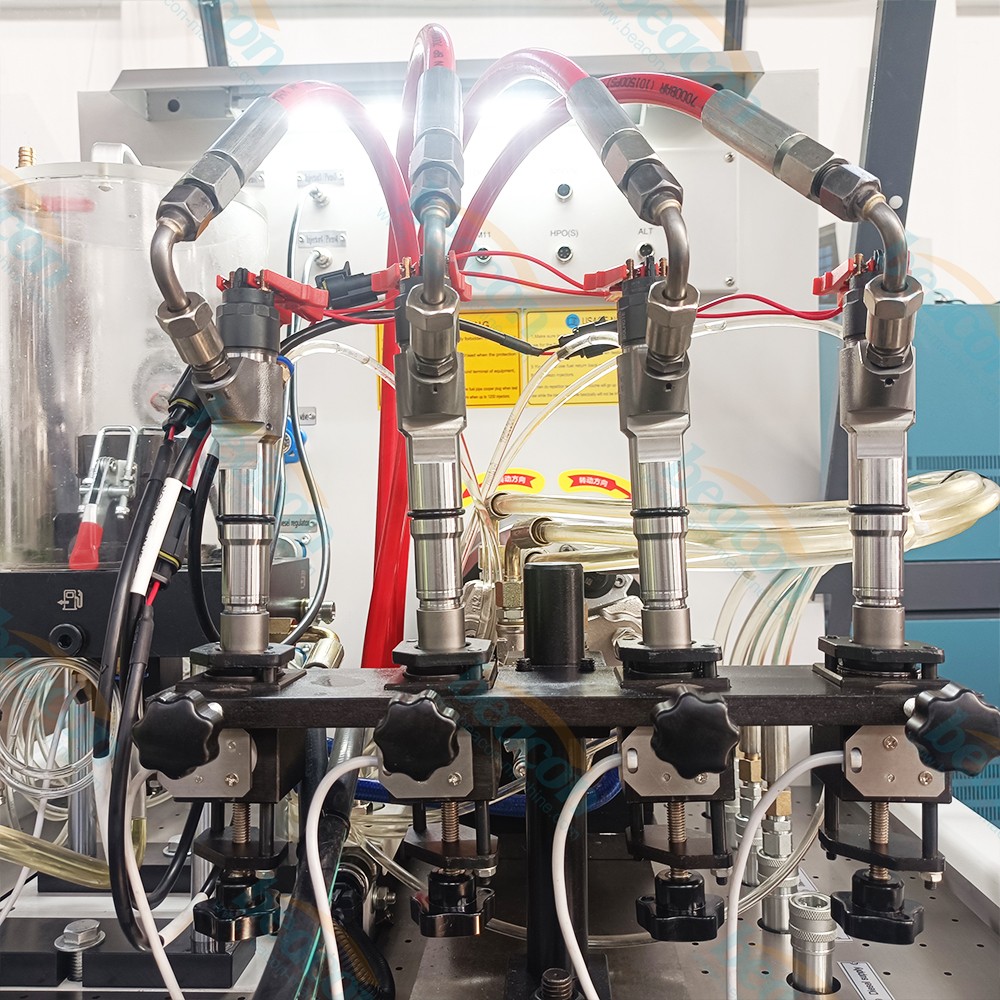

THIS MODEL CAN ALSO CUSTOMIZE 4 INJECTOR TESTING WITH 4 INJECTOR FLOWMETERS:

BC808 HEUI EUI EUP Common Rail Injector Pump All In One Test Bench Advantage

Comprehensive All-in-One Testing: Supports Injectors, Pumps, EUI/EUP, HEUI, and HEUI actuation pumps in a single machine.

Wide Brand Coverage: Fully compatible with Bosch, Denso, Delphi, Caterpillar, Cummins, and Siemens systems.

Intelligent Coding System: Automatically generates fuel quantity correction codes (QR/IMA/IQA) for precise injector calibration.

User-Friendly Interface: Features a 15-language support system and a separate main control console for flexible operation.

Precision and Stability: Uses high-precision flow sensors and an intelligent PID algorithm for stable pressure control and accurate data.

Robust Build: Features a new cam box for EUI/EUP testing and universal fixtures for fast and easy clamping of various components.

Remote Support: Supports remote assistance via the internet for software updates and troubleshooting.

parameter

| No. | Items | Technical Parameter |

|---|---|---|

| 1 | Main Motor Speed | 0-4000 rpm (Adjustable) |

| 2 | Motor Power | 11KW / 15KW / 18.5KW / 22KW (Optional) |

| 3 | Fuel Injector Open Voltage | 12V, 80V, 150V |

| 4 | Injector Opening Frequency | 0-1000 HZ (Accuracy: 1 HZ) |

| 5 | Fuel Pressure Control | 0-2400 Bar (Accuracy: 1 Bar) |

| 6 | Oil Tank Volume | 60 L |

| 7 | Power Supply | 380V / 220V (3-Phase) |

| 8 | Machine Dimensions | Approx. 190 * 110 * 185 cm |

| 9 | Net Weight | 1000 Kg |

video

Our factory

Certification

Our Customers

RELATED PRODUCTS

Language

Language